Excellence can be found not only in the field of modern industrial production, but also in many traditional crafts and trades. But technological change is also making itself felt here. The example of Boutroué, which has succeeded in melding traditional engraving with advanced technology, shows how this can be achieved. In the field of wire erosion, it has been consistently using Mitsubishi Electric systems since 2006.

Symbiosis of high tech and outstanding workmanship.

“Our services are called for, for example, when it comes to marking top products for the luxury goods, jewellery and watchmaking industries, for instrument making or fashion accessories,” says Laurent Savonneau, owner of Établissements Boutroué in Paris. The tradition-steeped firm, which probably dates back to the time of the French Revolution, is the last remaining master engraver in Paris. Some of its customers are world-famous companies from such sectors as fashion and fashion accessories, goldsmiths, instrument makers, perfumers, and makers of wines and spirits. Boutroué also makes dies for medals and coins, sports trophies, metal labels for high-quality products as well as emblems, stamps, punches for jewellers, embossing stamps for sketch pads, branding irons, prototypes and parts for the luxury goods industry – from machining through to finishing. In addition to meeting the highest standards of durability and quality, what all these applications have in common is that they also have to satisfy exceptionally exacting aesthetic requirements.

In 2014, Boutroué was named a Company of Living Heritage by Emmanuel Macron, then Minister of Economic Affairs, with 200 other companies.

“As with many traditional crafts, the art of engraving is gradually dying out, so that we’re barely able to find suitable staff,” says Savonneau with regret. Moreover, in the fashion sector, for example, the deadlines are incredibly tight, he adds. When accessories are shown at fashion shows, the first orders come in within hours and then have to be completed as quickly as possible. This is why the company today consistently draws on state-of-the-art technology. The machine shop is therefore chock-a-block with highly advanced CNC-controlled machines such as milling machines, lathes, laser-cutting and engraving systems, EDM systems and other equipment for the fast and efficient machining of metal components. Thanks to this transformation, the firm has succeeded not only in consolidating its traditional customer base, but also in attracting new customers in all branches of industry – from small businesses to large corporations. These require such items as precision-manufactured prototypes, die-casting and injection moulds and electrodes for die-sinking EDM. Boutroué’s production is designed for small to medium-size quantities from single items to several hundred components.

Traditional engraving with advanced technology.

“Almost every customer who comes to us needs detailed advice and assistance,” Savonneau adds. The issues concerned are almost always unique and often also involve aesthetics and design, calling for close attention to the customer’s various ideas. Even old technology often has to be given a new lease of life with modern means, e.g. in the case of a manufacturer of elaborately embossed cutlery who needed new embossing dies. Here Boutroué was able to help by scanning old designs and using modern reverse engineering methods to create new embossing dies for production. Other tasks involve high-quality jewellery components for goldsmiths, an area in which Boutroué has meanwhile made a name for itself as a specialist in the electrical discharge machining of precious metals. The firm therefore attaches great importance to wire EDM.

Laurent Savonneau is visibly proud of his modern wire EDM systems.

Our services are called for, for example, when it comes to marking top-quality products in arts & crafts, fashion and instrument making.

Laurent Savonneau, owner of Établissements Boutroué

“We had our first contact with Boutroué in 2006,” recalls Mathieu Ogier, sales engineer at Mitsubishi Electric’s sales partner Delta Machines in Morangis, France. Boutroué had been operating two wire EDM systems from other manufacturers for seven years but wasn’t satisfied with them. The decisive factor was essentially that the old systems could no longer sufficiently satisfy the market’s increased precision requirements, causing some jobs to be outsourced at high cost. The search for alternatives then led to talks with Delta Machines.

“It didn’t then take us very long to choose Mitsubishi Electric systems, as we were impressed by both the quality of the technology and the supplier’s service readiness,” Savonneau reveals. An invitation to a nearby trade fair demonstration provided the opportunity to experience the systems in action, obtain comprehensive information on all features and also see parts produced with them. This live demonstration proved highly persuasive, he adds. Further questions were then clarified in several rounds of talks, including visits to users.

Some of the firm’s customers are world-famous companies from such sectors as fashion and fashion accessories, handicrafts, instrument makers and makers of wines and spirits

Two further factors played a special role in the choice. Firstly, the geographical proximity of the Morangis branch was essential as a prerequisite for rapid support in the event of a need for advice or service. Even more significant, however, was Delta Machines’ willingness to take the decommissioned machines in payment and handle their marketing as part of the deal for the two systems, an FA10 and an FA20. Boutroué would not otherwise have been able to keep the disused systems in the very cramped workshop while waiting for a buyer.

The company with a long tradition.

Barbs machined with wire erosion

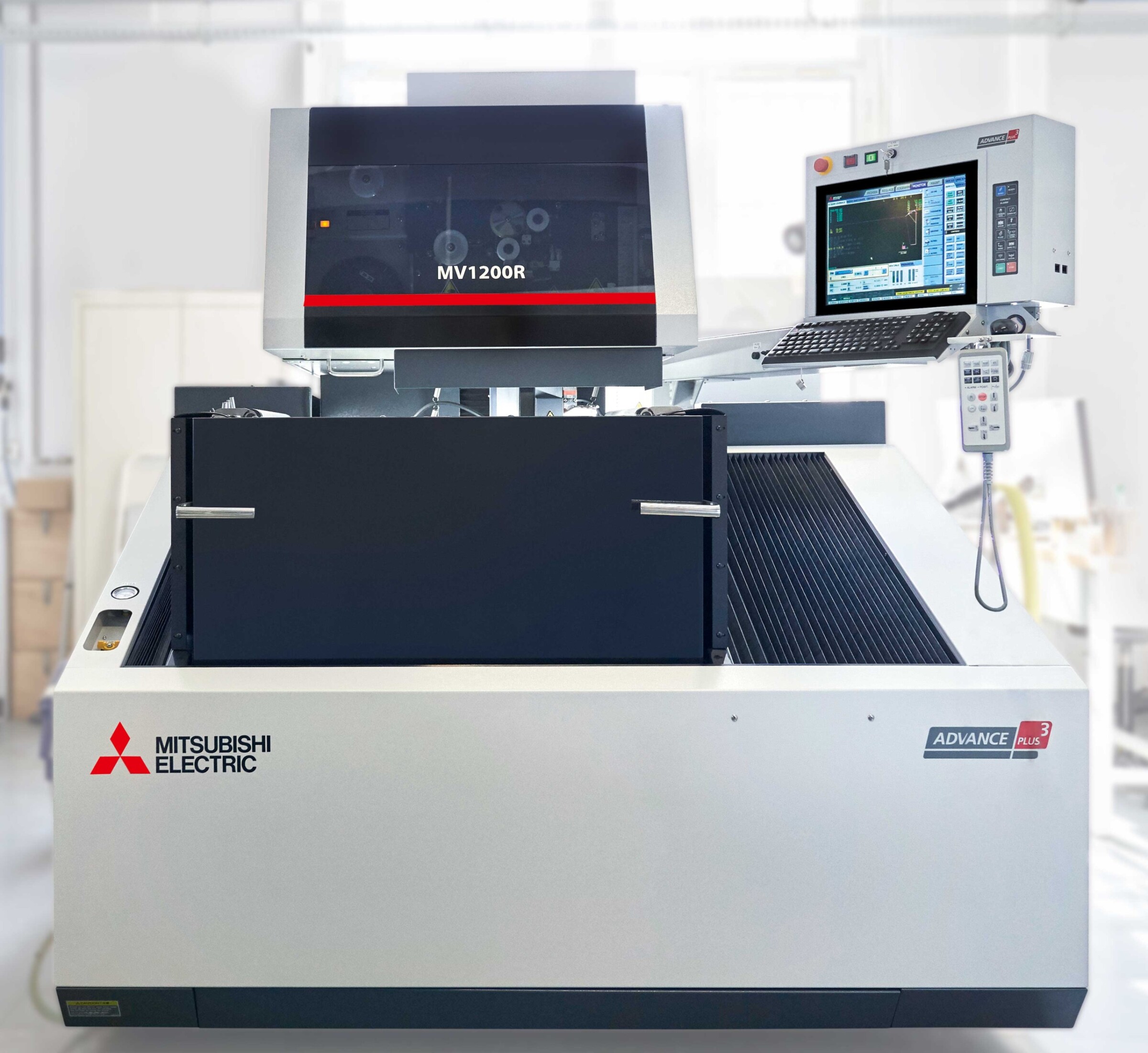

”In 2016, because of the advances in technology, we bought new wire EDM machines and once again opted for Mitsubishi Electric,” says Savonneau. With accuracies in the 1/100 mm range, the new-generation MV1200R and MV2400R systems are not only more precise than the old systems, but also feature other striking improvements such as automatic wire threading even in narrow kerfs so that production can immediately resume. This was an important factor, he claims. Although the old FA systems already had automatic threading, the device had to return to the beginning of the kerf for this purpose. After threading, the entire cut portion of the kerf had to be traversed again, which, depending on the complexity of the cutting geometry, sometimes resulted in a considerable loss of time.

The Mitsubishi Electric MV1200R wire EDM machine in operation at Boutroué since 2016 permits automatic re-threading even in narrow kerfs

It didn’t take us very long to choose Mitsubishi Electric systems, as we were impressed by both the quality of the technology and the supplier’s service readiness.

Laurent Savonneau,

owner of Établissements Boutroué

The firm’s decision in favour of Mitsubishi Electric was taken not least because of the quality of the systems. It has rarely had to resort to the after-sales service, which is due to the fact that the interior of the machines largely originated from Mitsubishi itself. “And what they’ve installed in it is of Rolls-Royce quality,” Savonneau confirms.

Quality at Rolls-Royce level.

High concentration while Savonneau operates the MV1200R

Name and place of company:

Ets. Boutroué

France

Founding year:

1885 (earliest records)

Managing Director:

Laurent Savonneau

Core business:

Industrial engraving, fashion accessories

Ets. Boutroué

60, rue de Wattignies,

75012 Paris, France

Tel +33-1-53-33-8883

Fax +33-1-53-33-8884

contact@boutroue.fr

www.boutroue.fr

Mitsubishi Electric

agent for France

DELTA MACHINES

3, rue du Docteur Charcot

91420 MORANGIS, France

Tel +33 1 60490974

www.delta-machines.fr

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com