Industry has a new top event to look forward to. At the beginning of May, the tool-, pattern- and mouldmaking world is meeting for the first time at Moulding Expo, the new trade fair in the technology portfolio of the Messe Stuttgart exhibition centre. And the signs are that the first-time staging of the new format will be a big success. Find out here why this is the case, what Messe Stuttgart is offering and what visitors can expect.

Moulding Expo Stuttgart

From Tuesday, 5 May, until Friday, 8 May, the premiere is taking place in the Land capital. The three envisaged halls amounting to 31,500 square metres of total space will be fully booked, with well over 400 exhibitors for the debut event. One of the main reasons for this positive response is that the strategy for the new trade fair was developed and coordinated in advance with the relevant industrial companies in this high-performance sector (EUR 8.8 billion sales in 2012). The event is also being supported by the foremost industrial associations. Serving as the technical sponsors are the Association of German Tool and Mould Makers (VDWF) and – new in this capacity – the Federal Association of Model- and Mouldmakers (MF). The conceptual sponsors of the new international trade fair are the German Engineering Association (VDMA) and the German Machine Tool Builders’ Association (VDW). “And this cooperation was really great fun for all of us. It was professional, business-like and marked by great earnest,” as Prof Dr Thomas Seul, VDWF President, stresses.

A totally new top event.

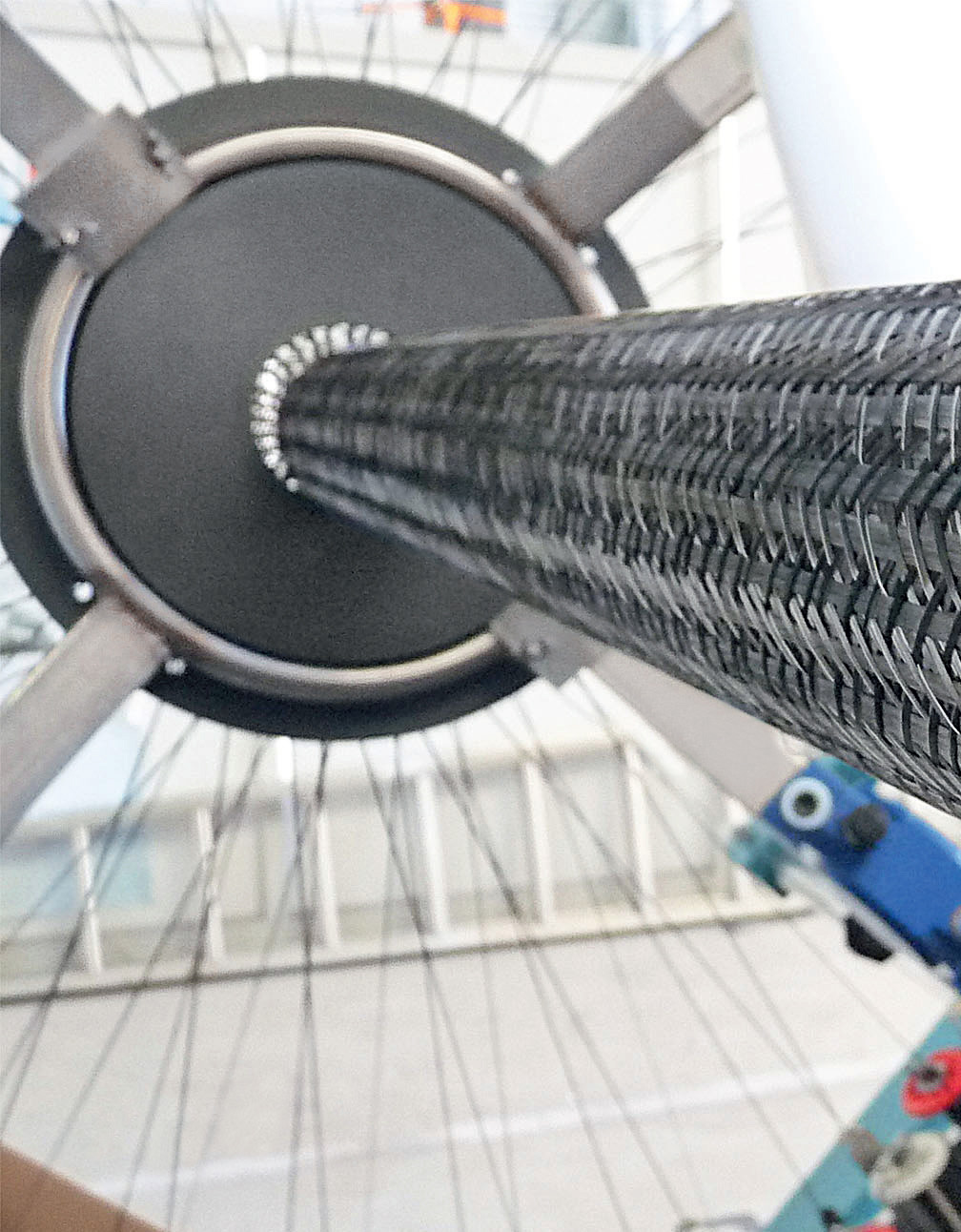

An example of how lightweight materials are produced can be found at the Institute of Aircraft Design (IFB) of the University of Stuttgart. Reels of carbon fibres attached to the inside of the rim of this 2 m tall braided wheel braid the 78 threads when it is turned.

What was the main motivation for establishing a new trade fair? “We had the impression that alternative events were confining themselves excessively to component supply business for tool- and mouldmaking. This is why we now want to offer the industry its own platform. Its purpose is to generate business directly and present itself to precisely those customers that will ultimately buy their tools and moulds,” says Seul. The fair is divided into several exhibition areas. First of all, classical tool- & mouldmaking and pattern- & mouldmaking with their shaping tools and moulds, plus various gauges, jigs and fixtures, will be on show. And then, visitors to Stuttgart can also expect systems and service providers in the field of plastics technology and metalworking, ranging from machine tool manufacturers and hot-runner suppliers to software firms. In addition, the associated users – those from the automotive sector, medical technology and the plastics industry, for instance – will also be exhibiting their products in Stuttgart.

The trade fair pavilion, a hybrid lightweight structure

In addition, Moulding Expo will also be functioning as an indicator of new trends. “What technological trends are taking shape? In what direction should tool- and mouldmakers be moving? And how will the machine parks, technologies and business models of the future look?” is how the VDWF President sees further themes of the trade fair. There will be a focus on the very latest technological processes, which will be presented on site. Visitors can find out, for example, how Embedded Systems are capable of importing intelligence into machines by storing in the tool or mould such information as article and production data, maintenance plans and all the process data from the first sample phase onwards. In this way, the tool or mould can be simply removed in one place and set up again somewhere else. “Offering these services and generating downstream business is absolutely essential for the sector. Demand-driven maintenance that the machine automatically requests rather than maintenance to schedule – this is a grand vision for the business models of the future,” Seul comments. The new trade fair format is rounded off with two accompanying events, the KSS trade fair for safe cooling, lubricating, cleaning, oiling, greasing and Control, the international trade fair for quality assurance. This means that visitors to Stuttgart will have the unique opportunity to obtain the whole spectrum of information of relevance to the industry on a single site. “We are firmly convinced that, on a single day at Moulding Expo, the trade visitor will be able to find out all he or she needs to know about the latest technologies and trends in the industry and meet all the leading lights in the industry on site. In this respect we’re offering the trade visitor unparalleled added value. It’ll be really good. I’m really looking forward to Moulding Expo!” says the VDWF President.

From the industry, for the industry.

Prof Dr Thomas Seul

Focus on brand-new technologies.

Prof Dr Thomas Seul is the Vice-President for Research and Transfer at Schmalkalden University of Applied Sciences and President of the Association of German Tool and Mould Makers (VDWF). The main areas of his research work can be found in the product development of plastics components and in tool and mould design, specifically for medical technology.

View inside a busy exhibition centre hall.

MOULDING EXPO

Ulrich Kromer von Baerle, Exhibition centre CEO on MOULDING EXPO

Name and place of company:

Moulding Expo Stuttgart

Moulding Expo Stuttgart

Definitely. Customer relations in tool-, pattern- and mould-making depend on mutual trust. Tools and moulds are skilfully crafted high-tech one-offs that are used by customers for the industrial production of large product series. At contract award, many parameters of the tool such as the tolerances of the products they will make or the use of semi-finished products often haven’t yet been defined. The toolmaker is thus becoming increasingly a consultant and service provider before and after toolmaking proper. Marketing and project work solely over the phone or by email will only work here to some extent. At the same time, technological progress is continuing to advance on all levels. So trade fairs are a useful shop window where any tool-, pattern- or mouldmaker can find out specifically and in detail about the latest technologies at a single location. In addition to the expertise in the companies, it is the quality of the supplied products and services – ranging from machine tools and standardised system components and materials through to software for production and organisation – that has a large influence on the excellence of the produced tools, moulds and patterns.

Trade fairs in the tool-, pattern- and mouldmaking sector are changing and Stuttgart is ready with its modern trade fair and congress centre that opened in 2007 to offer the sector a fitting home. The premiere in May 2015 will be a success – this is demonstrated by the extremely gratifying level of exhibitor registrations. And in the coming years, on a biennial basis, this showcase for German tool- and mouldmaking will again be taking place in the Land capital.

Internationally, tool-, pattern- and mouldmakers in Germany produce top-quality work, yet it is small and medium-size enterprises that predominate. Customers are often unable to see the toolmaker as a partner and supplier of solutions; nor do they realise that tools and moulds are key elements in a complex product development and production context. In the last few years, the idea of networking has taken root increasingly in the sector. “German tool- and mouldmaking is a brand,” is how Prof Seul puts it. This brand can and will be shown, cultivated and promoted in Stuttgart. This can also be seen as a bid to strengthen Central Europe’s position as a centre of manufacturing industry.

It shows that everyone involved means business. Messe Stuttgart is a service provider and, to breathe life into Moulding Expo, has attracted the participation of the industry’s four leading associations as its conceptual and technical sponsors. These are the Association of German Tool and Mould Makers (VDWF), the Federal Association of Model- and Mouldmakers (MF), the German Engineering Association (VDMA) and the German Machine Tool Builders’ Association (VDW). “From the industry for the industry” is the Moulding Expo’s motto. And this is being brought to life in the committee meetings and the joint events and gatherings in the preparation of the fair.

If production is possible all over the world with the same machines, the same software and the same set of digital data for tool design, then it is the technical expertise that makes the difference. This covers such skills as problem-solving competence, being able to spot flaws early on in production and seeing things from the customer’s point of view. And in the injection moulding of plastics, thinking in terms of the shaping and stamping of sheet metal or the casting of metal. This is made possible by the high standard of apprenticeships and further training. Moulding Expo is therefore a lobby for the industry. We want to give up-and-coming tool-, ¬pattern- and mouldmakers an impression of the exciting and varied activities in the industry.

The ideas embodied in “Industry 4.0” are already “unconsciously” established in the minds of tool-, pattern- and mouldmakers already operating successfully on the market today and are a permanent feature of their everyday work. The industry puts aspects of Industry 4.0 into practice not only in automation but also in up- and downstream processes in development and on partner and customer sites.

There’s a whole host of challenges that could be jointly tackled, challenges that are giving tool-, pattern- and mouldmakers are hard time. For instance, the continuing squeeze on margins caused by globali-sation. And then there are the fluctuations in the business cycle, the migration of target markets to the Far East, and the shortage of skilled staff due to demographic change.

Exhibition centre CEO

MOULDING EXPO

Ulrich Kromer von Baerle has been President and CEO of Landesmesse Stuttgart GmbH (formerly SMK – Stuttgarter Messe- und Kongress GmbH) since 2001. He is in charge of the company as a whole, of trade fair business and interdisciplinary tasks. Von Baerle has also been Managing Director of Projektgesellschaft Neue Messe GmbH & Co. KG since 2004.

Ulrich Kromer von Baerle

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com