Cryogenic Ltd, a leading supplier of high field superconducting magnets and low temperature measurement systems, has installed a high performance Mitsubishi MV1200R wire cut EDM. Supplied to the company’s Acton, West London facility by exclusive UK sales and support agent, HK Technologies, the machine has eliminated the need to outsource wire EDM operations and helped expedite the progress of new measurement devices.

Mitsubishi MV Series wire EDM cuts the ice at Cryogenic Ltd

The cryogen-free measurement systems designed and manufactured by Cryogenic Ltd need to accurately assess and record temperatures as low as 1°K (-272°C), typically for the characterisation of new materials intended for use in extreme conditions. Cryogen-free is preferred because liquid helium is an expensive consumable which limits the application of low temperature technology, especially in countries that do not have indigenous sources of liquid helium.

George (left) and Paul Rowledge (right) in front of the MV1200R Grand Tubular

“We were previously subcontracting our wire EDM requirements and realised how useful the process could be,” explains Dr Yury Bugoslavsky, Senior Project Engineer. “We tend to hold all of our key technologies in-house, so acquiring a wire EDM was deemed part of our general development as a sector leader.” The machine selection process commenced with inviting a small number of EDM sales representatives to the London headquarters of the 70-employee, £10 million turnover company.

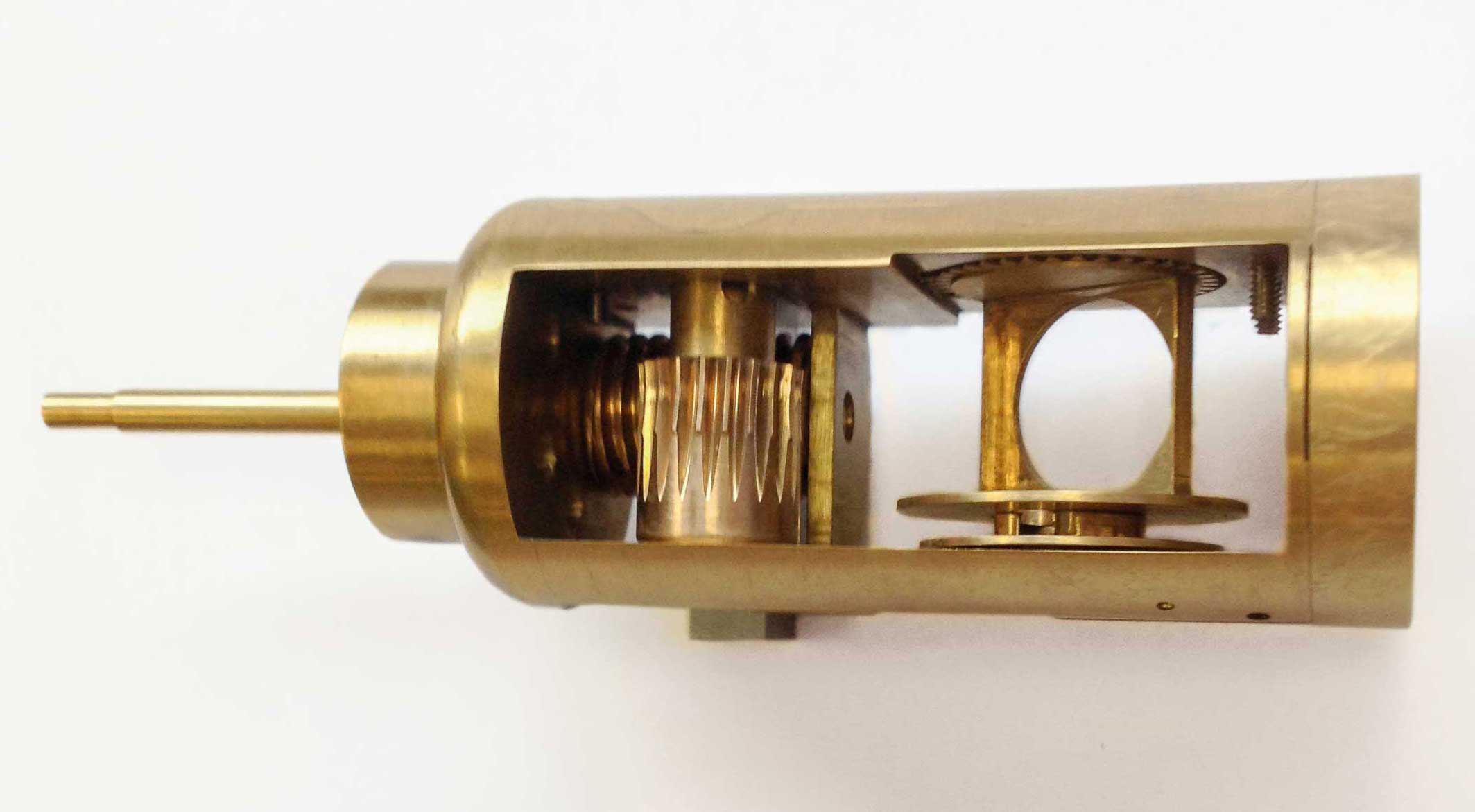

Parts of the low-temperature probe manufactured by Cryogenic Ltd

“The presentation by HK Technologies was by far the best,” states Dr Bugoslavsky. “The Mitsubishi MV Series has certain key advantages that set it apart from competitor models, such as cylindrical drive technology, for example.” Mitsubishi’s revolutionary cylindrical drives remove many of the pitfalls associated with linear drive motors. At the core of this breakthrough are innovative tubular shaft motors deployed to move a number of axes. These motors prevent ‘cogging’ and ensure smooth and highly controllable movements.

“To achieve progress with new low temperature measurement devices we are constantly looking at ways to enhance component precision,” says Dr Bugoslavsky. “The design configuration of the MV Series is a significant benefit in this respect.” The new cylindrical drive design on the Mitsubishi MV Series prevents many issues associated with linear drive systems, which trap heat behind the iron back-plate on the magnetic mount. This can cause geometric issues or lead to high electricity consumption due to cooling requirements. Furthermore, there can be problems aligning the linear drive motors together on the driveways without generating a ‘crabbing’ effect.

Left Sample stage for measuring physical properties of materials in a vacuum and at low temperatures

Cryogenic Ltd opted to install a Mitsubishi MV1200R, a specially designated ‘high performance’ model in the MV Series. Installed in February 2013, the machine features four-axis (XYUV) linear shaft motors and one-piece, four-sided hardened tables. Both X and Y axes are mounted directly to a set of ways on the ‘T’ cast base. This style of direct axis mounting removes the squareness and repeatability issues associated with stack-table designs, providing higher rigidity and smoother movement. The MV1200R can accommodate workpieces measuring up to 810 x 700 x 215mm.

“During the commissioning period, initial cutting trials on a stainless steel cube measuring 10mm³ demonstrated accuracy of ±1µm,” says Dr Bugoslavsky. “We knew we had made the right choice.”

Today, Cryogenic Ltd uses the machine day-in, day-out to produce intricate, complex small parts with unusual forms from materials such as copper, brass, aluminium and stainless steel. For example, copper components might form part of measurement probes used to study the thermal conductivity of materials at extremely low temperatures. Similarly, brass gearbox parts might be used at very low temperature and strong magnetic fields to measure the electrical resistance of anisotropic materials.

Below Miniature rotating sample stage for operation at a temperature of down to 2 Kelvin (-271°C)

“As well as eliminating outsourcing costs, the Mitsubishi MV1200R has also imparted greater levels of control in our manufacturing process,” concludes Dr Bugoslavsky. “We have some customers who demand very specific requirements and extremely short lead-times, particularly for prototypes.”

George Rowledge at work

Cryogenic Ltd is a vertically integrated operation in that it designs and builds using in-house facilities, then tests and installs its equipment. The use of internal resources is preferred as it allows the company to control all the critical elements of the production process. The production facilities today include a substantial machine shop: aside from multi-axis Mitsubishi wire cutting, the company operates several milling and turning machines.

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com