With its focus on precision, jobshop SNOP61 SARL in Athis de L’Orne in Normandy, France produces high-precision components – anything from prototypes and one-off items to medium series – mainly using materials that are difficult to machine. With his pronounced interest in high-grade technology, owner and Managing Director Frédéric Tertre has established his company as a specialist in precision machining beyond the immediate region.

Frédéric Tertre. Managing Director of SNOP61

Of course, that’s where the reliable wire threader of the MV from Mitsubishi Electric proves indispensable. These wire-cutting machines work very reliably anyway.

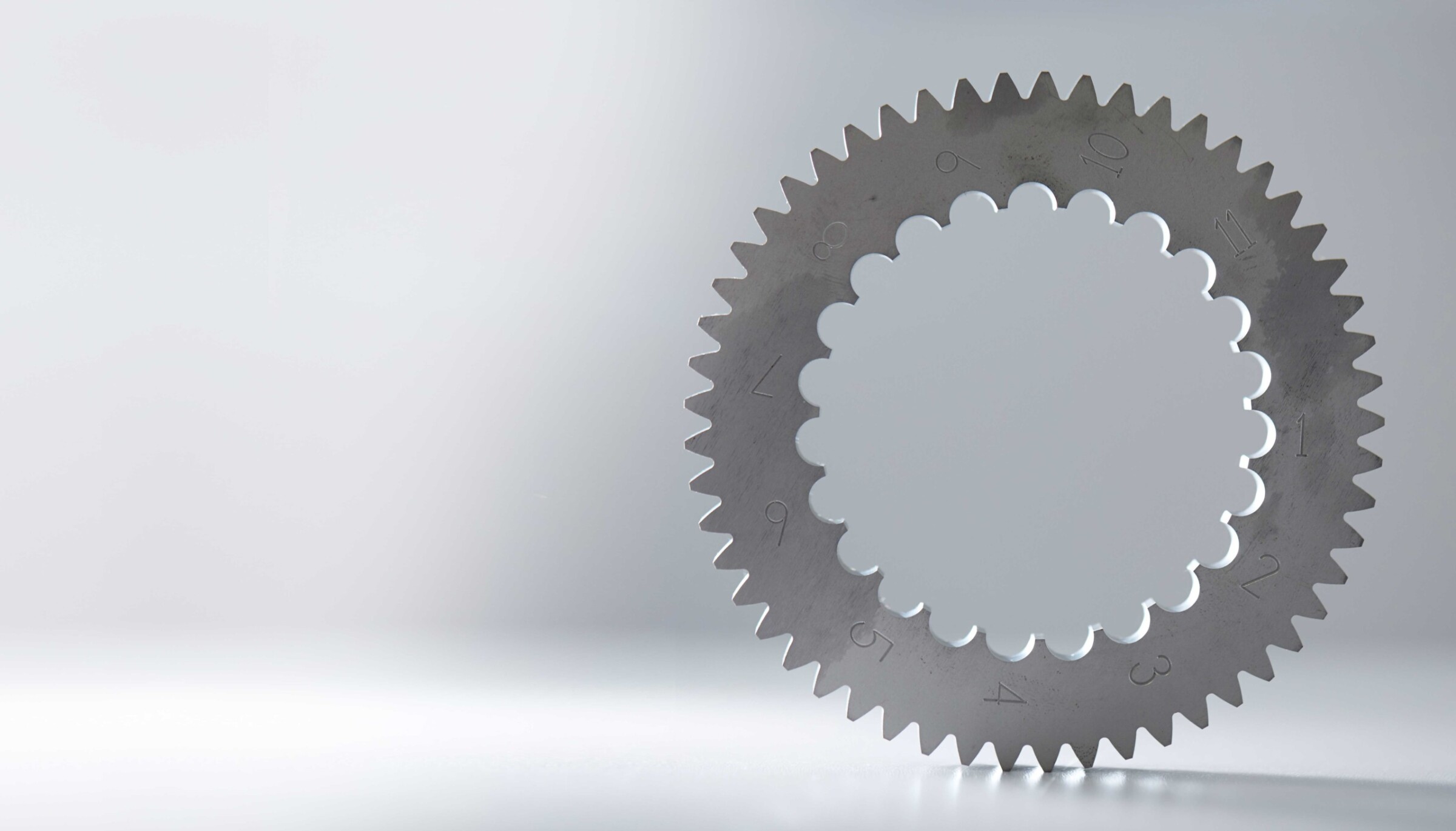

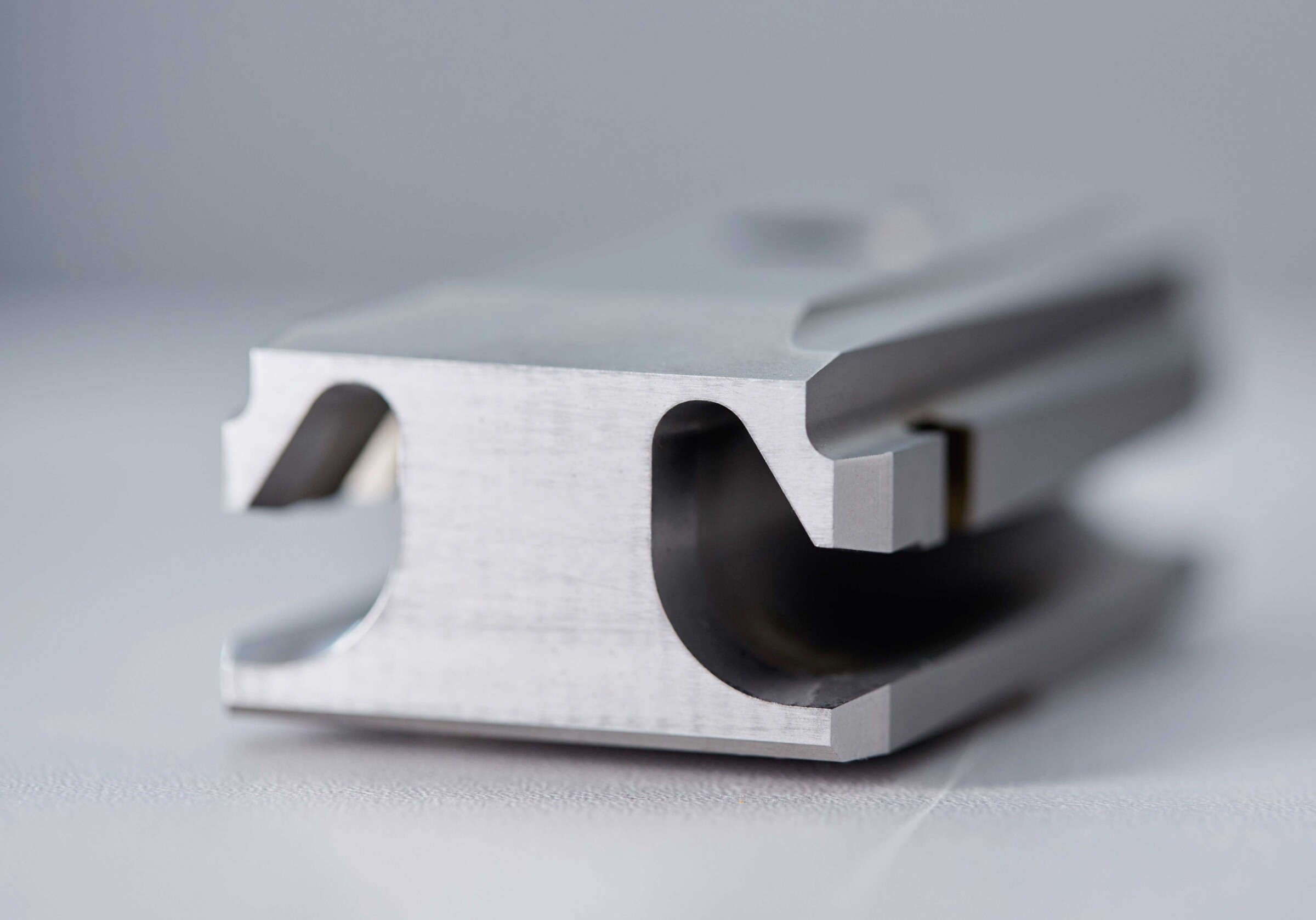

Concealed behind the unassuming frontage of the business premises in Athis de L’Orne is top-flight production equipment. The company has several state-of-the-art 3- and 5-axis machining centres as well as a number of high-grade lathes and precision grinding machines. Pride of place, however, is taken by the two wire EDM systems MV2400R and MV1200R from Mitsubishi Electric purchased by Tertre in 2016 and placed in a separate enclosure in the workshop. He explains the reasons for this: “Accuracy between 3 and 5 µm calls for extreme cleanliness and air-conditioning.” The two EDM systems are largely responsible for the fact that the jobshop is now appreciated beyond the region for its dependable precision machining. The company produces parts as single items and in very small series for tool- and mouldmakers, among other things for stamping tools, forming dies and injection moulds. It also machines wear tools for plastics machines, e.g. superfine nozzles for the extrusion of glass fibres. In addition, the precision specialist machines prototypes and series parts exposed to extreme wear. These can be components for special-purpose, assembly, textile and packaging machines, such as guide sleeves, nozzles, and guide and deflection levers. The experts in Athis de L’Orne have also produced bushings for the aviation sector. So that these components perform durably, they are made of unalloyed tool steels, cold- and hot-work steels, and high-strength and hardenable steel alloys.

Intricately shaped wire-cut nozzles for exhaust gas systems.

The advantages of wire-cutting.

Using such materials, precision components can be milled these days on extra-heavy-duty 3- and 5-axis machining centres. But Tertre also appreciates the benefits of wire-cutting. The process, he says, is slow, “but with wire EDM we generate high-precision components that meet all the requirements of a superlative surface finish in a single cycle”. A highly beneficial feature in his view is that the wire EDM systems are capable of running entirely unsupervised. “Of course, that’s where the reliable wire threader of the MV from Mitsubishi Electric proves indispensable. These wire-cutting machines work very reliably anyway,” Tertre adds. To keep costs down despite the slow machining speeds, the specialists in Athis de L’Orne cut several components out of single large plates. The MV2400R and MV1200R were purchased precisely for this reason. Although he had acquired plenty of experience with the highly dependable FX20 wire-cutting machines from Mitsubishi Electric starting in 1998, the new machines have a much larger workspace. As a result, the jobshop can now produce not only small components in series in an unmanned process, but also handle large workpieces measuring up to 800 x 400 x 150 mm. The latter workpieces can be machined into hold-down devices for forming dies.

With their sharp edges and smooth surfaces, freely shaped small components of hard steel alloys can only be machined with wire EDM.

The advantages of wire-cutting.

The MV2400 machines are much faster than the trusty FX20. Consequently, the jobber can machine a large number of components made of difficult-to-machine materials up to 30 per cent more cheaply, says Managing Director Tertre. Furthermore, the MV2400R is equipped with the optional digital fine finishing generator (DFS). In combination with top-quality wire, they achieve a superb surface finish. “This accelerates throughput considerably. The wire-cut components can be installed in stamping tools or special-purpose machines without elaborate reworking,” Tertre reports. The MV machines thus also contribute to high flexibility and short delivery times at the French jobshop. Moreover, the MVs are easier and more comfortable to operate than the FX20s, which is why they are preferred by skilled staff. The CNC control built onto the machine displays the current and programmable production parameters much more neatly and clearly.

The experts at SNOP61 prefer working at the two wire EDM systems of the MV series because of their simple and straightforward operation.

Production around the clock.

To minimise set-up and tooling time, the specialists in Athis de L’Orne program both wire EDM systems on an external MasterCAM CAD/CAM system. “So that the machine operators can access the data in the CAD/CAM system directly, we have positioned the PC workstation in the air-conditioned enclosure next to the wire-cutting machines,” Tertre explains. This also helps to reduce unproductive downtime, accelerate throughput and boost productivity and profitability. At the company, the two MVs are kept running 24/7, workload permitting. “We invested in a MV2400 and a MV1200 so that we would have wire-cutting machines that complement one another while also being interchangeable. This means that we can double our productivity if we use the two machines in parallel for a single production job. Alternatively, we can sustain our productivity and keep to deadlines when one machine is laid up for maintenance or servicing,” says Tertre explaining his far-sighted production strategy.

Shaping components of difficult-to-machine materials up to 30% more cheaply.

Name and place of company:

SNOP 61

France

Founding year:

1986

Managing Director:

Frédéric Tertre

Employees:

13

Core business:

Production of high-accuracy precision parts made of high-strength, hard and hardenable steel alloys, as single items and in series, for stamping tools, forming dies and special-purpose machines in the plastics, food, automotive and aerospace industries

SNOP 61

ZI. La Colomblée

61430 Athis de L’Orne, France

Tel +33 (0)23364 4372

Fax +33 (0)23396 1860

frederic.tertre@snop61.com

I started off as a chef. Later, when doing maintenance work on machines, I discovered my special interest in technology and mechanical engineering. After my national service I worked as a design engineer and technician. My then employer worked with component supplier SNOP61, which is how I got to know its owner and managing director. And that gave rise to the offer to continue the business on his retirement. I bought the business in Athis de L’Orne in 2008.

We were badly hit by the global financial crisis in 2009. Only shortly after my takeover, I had to face and survive a 35 per cent drop in sales. With my perseverance and enthusiasm for innovative technology, I soon mastered the crisis. Since 2010 the company has been growing steadily, which is partly due to the continuing investment in high-grade equipment and machines.

My employees and I are on very friendly working terms. For me, the workforce is a company’s biggest asset. Only committed employees integrated in the company’s strategy are capable of pursuing shared goals and contributing to success. We are also on good and collegial terms with the other production firms in the region. We try to help one another out. At the same time, our strategy is to consistently supply the best-possible precision and quality. We always focus on components that call for exceptional accuracy in their machining.

I want to expand production by investing in innovative technology. About 10 per cent of annual sales is in my view the right investment sum. This will increase our capacity while also extending our technological scope for machining with greater precision and reliability. For example, I’d like to build up our wire EDM activities with extra high-performance wire-cutting machines. In addition, we shall also be looking at additive machining and probably invest in this technology as well. Over and above this, I have a special interest in automating production processes on the principles of Industry 4.0. This should enable us to dependably produce complex precision parts made of difficult-to-machine materials even more cost-effectively, flexibly and faster from now on.

We’re planning for steady growth. I’m confident that we can double our sales in five years.

Managing Director

SNOP61

Frédéric Tertre Managing Director

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com