The customer list of Fischer & Co KG in Sinsheim includes well-known names from the automotive, electronics, pharmaceutical, machine manufacture and other industries. The medium-sized family business develops and builds injection moulds for the production of plastic parts. The machine park, which also includes two wire EDM machines from Mitsubishi Electric, is suitably opulent. We talked to Helmut Fischer, head of toolmaking, and two of his colleagues, programmer Uwe Oehmig and toolmaker Eduard Steinke.

“We know what we’re looking for.”

An opulent machine park.

Two of these machines are from Mitsubishi Electric. When and why did you choose them?

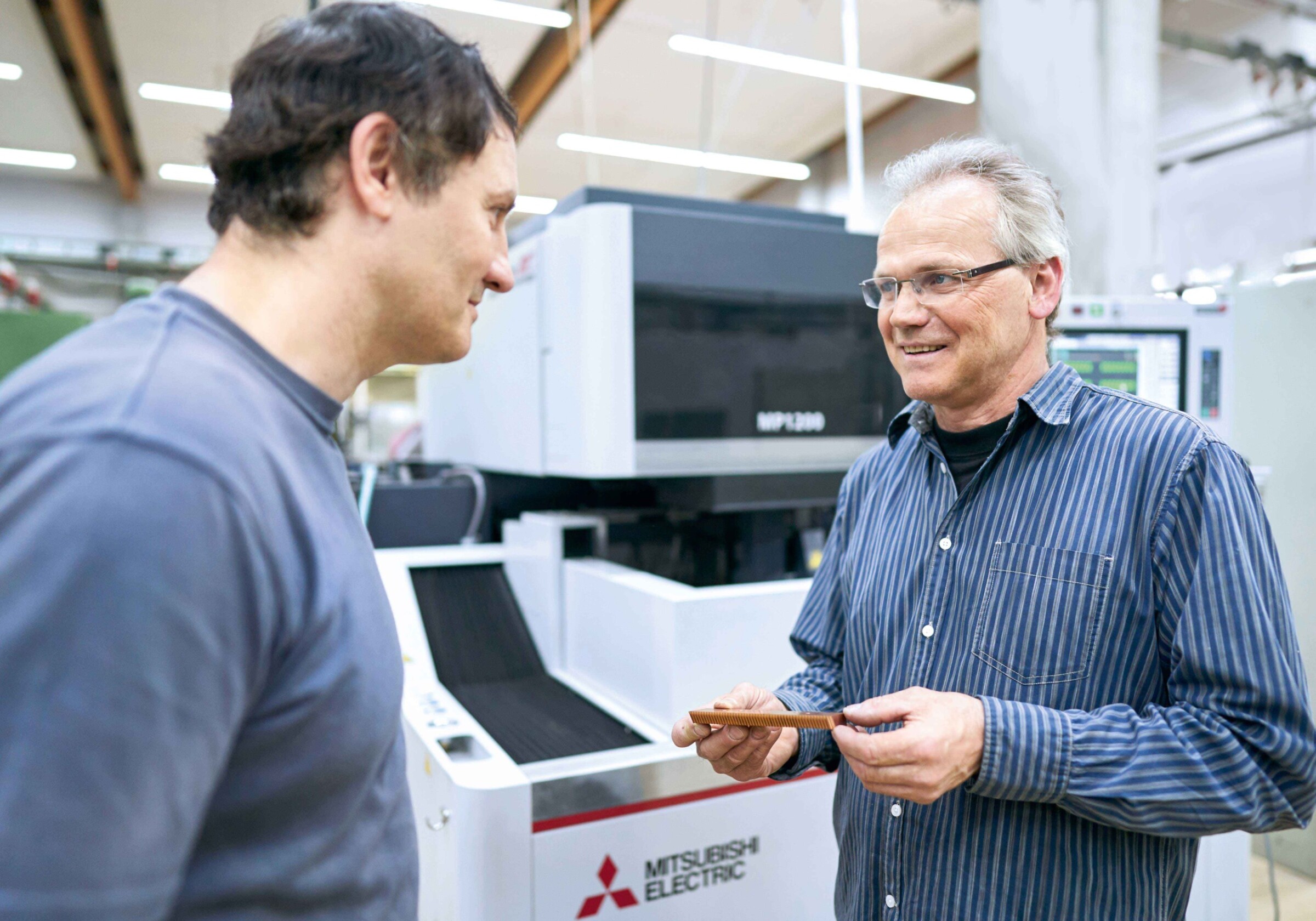

Oehmig: About five years ago, for a variety of reasons, we urgently had to expand our wire EDM machining capacity. So we searched the market to see which supplier had the machine that would best meet our requirements. And that was Mitsubishi Electric. We bought the first wire EDM machine, type MV2400R, in 2015. We were absolutely delighted with its performance and precision. And this is why, a year later, the second machine was added, an MP1200.

When you talk about performance, do you mean the specific speed of machining during cutting?

Steinke: For me as a toolmaker, there is another aspect that is very important when it comes to performance: how easily a machine can be retooled when an order is changed. Retooling is unproductive downtime that should be kept as short as possible so that the machine is up and running again as soon as possible. And retooling on both Mitsubishi Electric machines is really quick.

And what do you do if the wire breaks?

Oehmig: This is where Mitsubishi Electric has improved its automatic wire threader. It works brilliantly.

Let’s come back to your EDM expertise. Did you still have to complete a training course at Mitsubishi Electric?

Oehmig: Yes, we attended a one-week practical seminar in Eisenach in 2015 and that made a lot of sense. Even though we knew the technology and the processes, we still had to learn how to use the new control system so that we can make best use of its functions and to their full extent.

Another factor you mentioned is rapid service. Have you ever had to resort to it?

Oehmig: Not really. We carry out regular maintenance work ourselves. And if I remember correctly, in all the years we’ve only had one issue, and we were able to settle it over the phone.

Helmut Fischer, Head of Toolmaking

20 years of wire EDM expertise.

Helmut Fischer, Head of Toolmaking

Automatic wire threading? Brilliant!

Fischer GmbH & Co. KG

Fischer GmbH & Co. KG

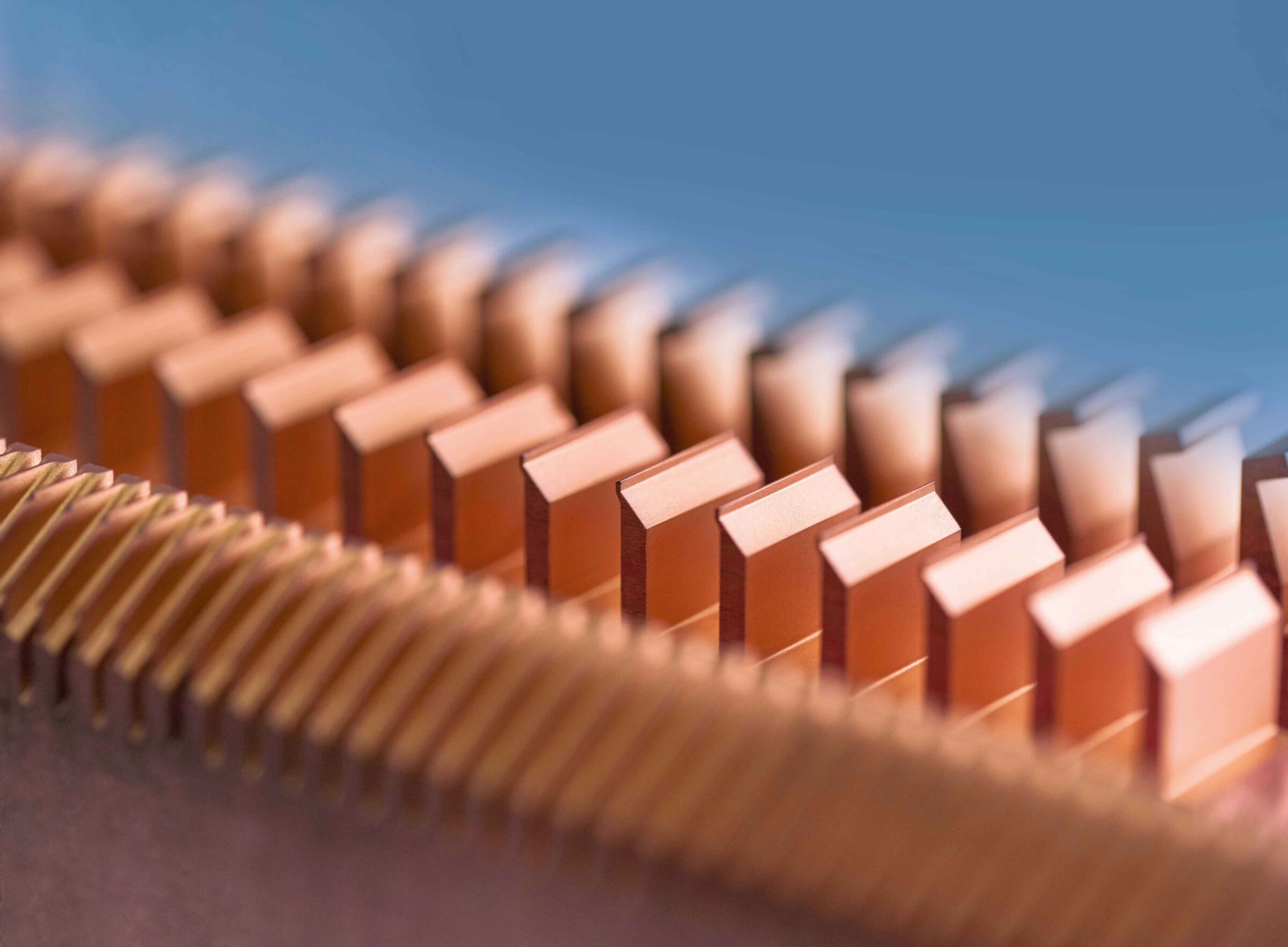

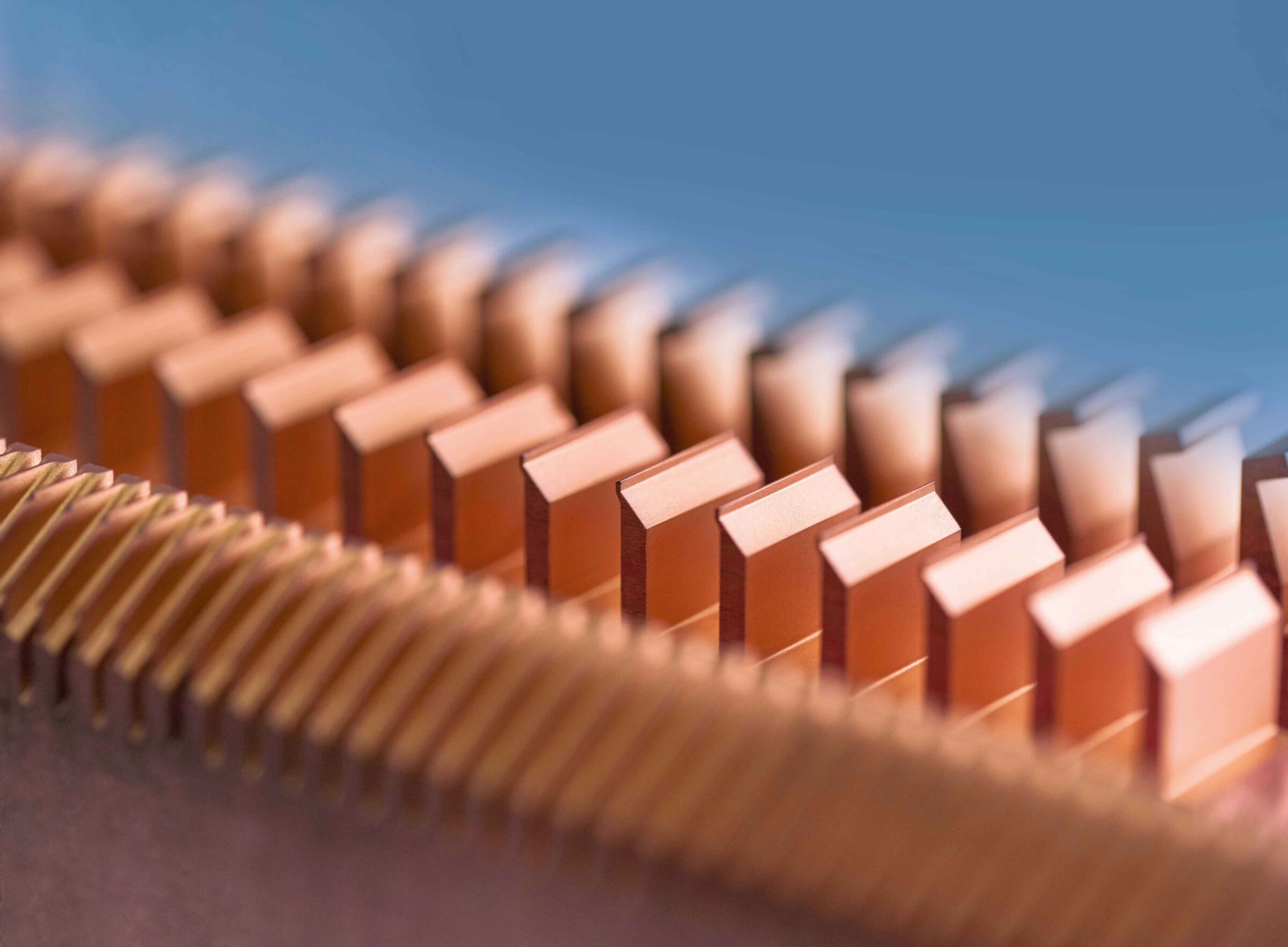

Toolmaker Eduard Steinke aligning the tool Shape-imparting elements of a mould

Eduard Steinke and Helmut Fischer discussing the results of their work

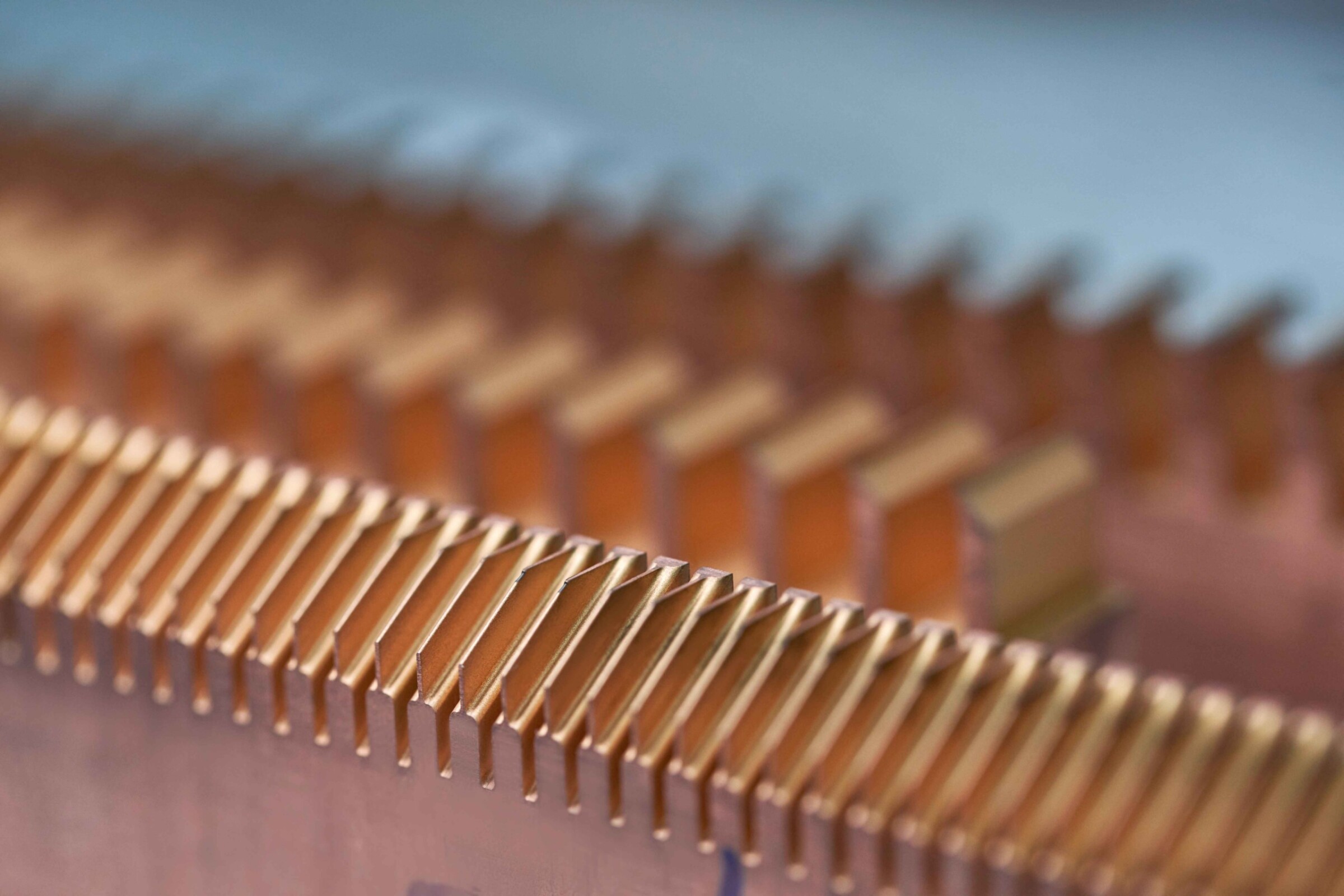

Wire-cut electrode with thin webs, clamped at an angle of 32°

Fischer GmbH & Co. KG

Name and place of company:

Fischer GmbH Co. KG

Germany

Founding year:

1973

Managers:

Werner and Karin Fischer

Employees:

240

Core business:

Technical injection mouldings and assembly parts

Fischer GmbH Co. KG

Uferweg 5

74889 Sinsheim, Germany

Tel +49 (0) 7261 / 684 – 0

Fax +49 (0) 7261 / 684 – 119

info@fischerwzb.de

www.fischerwzb.de

Without mentioning sales figures, we’re doing well economically and currently employ about 240 people. The order situation is good; firstly because we are quite broadly positioned in terms of target groups, and secondly because we manufacture our customers’ products here in Sinsheim on their behalf. We not only have the full range of expertise in-house, but also the technical prerequisites for toolmaking, production and assembly. And we’ve invested a great deal in the expansion of this capacity in recent years.

In assembly, we finish, combine and install components on various assembly machines and systems using a variety of technologies, such as reel-to-reel processes, inline moulding, ultrasonic welding and so forth. In production we operate 70 injection moulding machines. This is where most of the preliminary products for these components are produced. In the toolshop, where the tools and moulds for these injection mouldings are produced, we have five wire EDM systems in addition to various CNC-controlled machining centres.

We mainly looked around at metalworking trade fairs. In principle all well-known manufacturers are represented there with their machines and there you can get the best information. In more than 20 years we have acquired a lot of expertise in wire EDM. We know what we’re looking for.

The decisive factors for us were above all an optimum price/performance ratio, ease of operation and rapid service – should we ever need it. And so far, I really have to say we’ve taken the right decision.

Of course. We can even verify it pretty accurately: depending on the complexity of a component and the machining parameters, the cutting speed of Mitsubishi Electric machines is higher than that of other suppliers. However, taking the entire range of products that we have so far cut on these machines into account, this value is not quite as high. Nevertheless, there is a very nice side effect: compared to our old machines, we save up to 30 % of the energy otherwise required during machining.

That depends on the complexity of the parts being cut. The good thing is that you can cut those whose machining is very time-consuming overnight or over the weekend. All we have to do is make sure there’s enough wire for cutting.

From tool steel we mainly cut the functional elements typical of injection moulds such as dies, mould inserts, punches and so on. Less often, we also cut copper and aluminium parts.

We are currently actually considering whether to purchase another machine; ideally one with a rotary table as an additional axis. There is, for example, the KfW Energy Efficiency Programme, under which investments in energy-efficient production facilities and processes are financially assisted with an extremely low-interest loan.

Head of Toolmaking

Fischer GmbH Co. KG

Helmut Fischer, Head of Toolmaking

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com