Discover your new machine now.

High-end for highest requirements

High-end for highest requirements.

Equipped for demanding tasks like in Formula 1.

Optimum solutions – customised, configured or standardised.

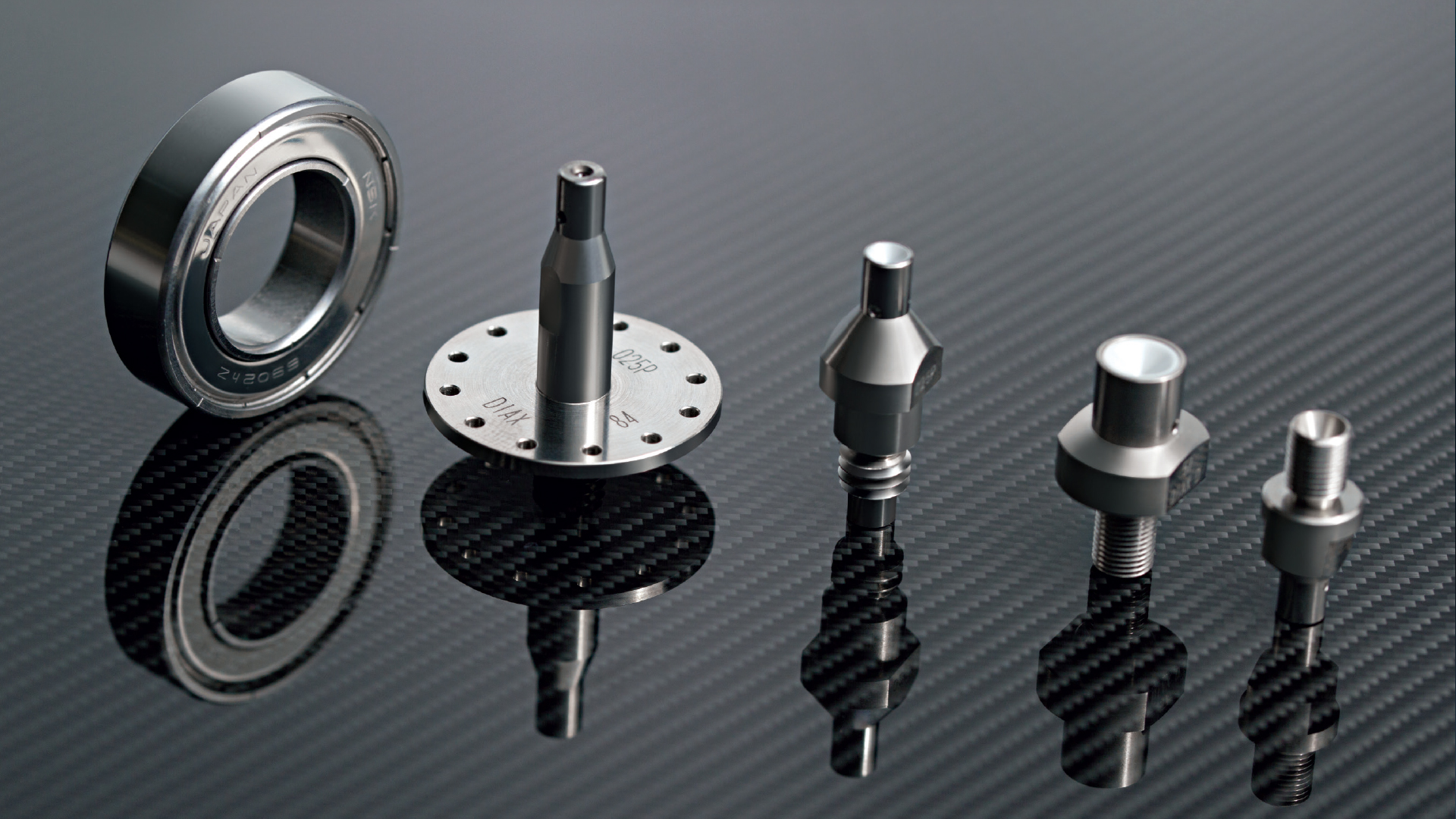

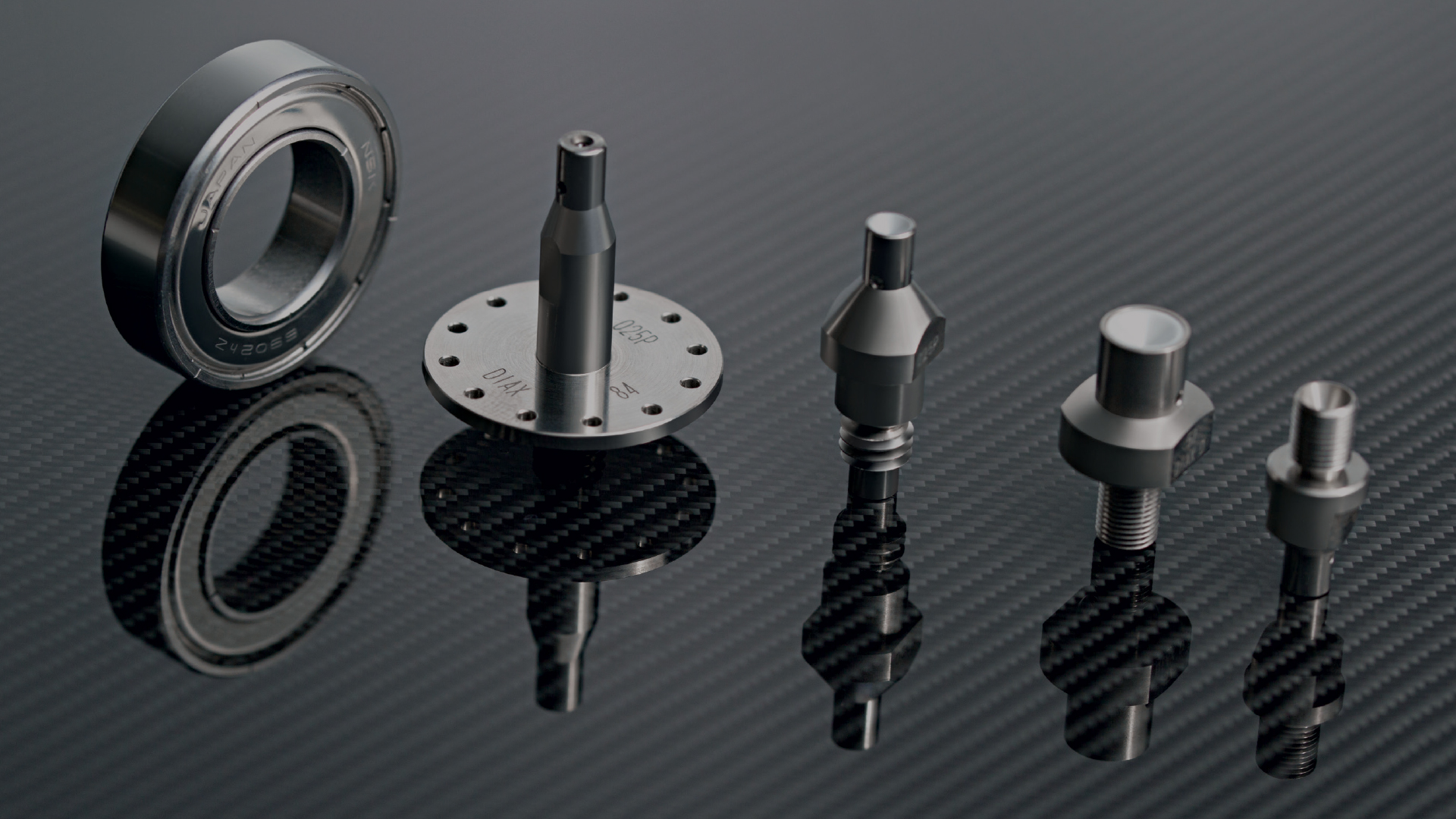

Spare and wear parts

Technology that inspires.

Today, operating a CNC machine no longer has to be complicated - the dialog guidance of the CNC helps even less experienced machine operators to reliably complete their tasks. The transparency of the machining processes on the EDM system and overviews of the maintenance status and resource consumption help with cost analysis and preventive maintenance. The analysis functions thus help to increase efficiency through better utilization of capacities and resources - and to further enhance the proverbial reliability of Mitsubishi Electric EDM systems.

produced EDMs

years of experience

patent applications per year

Service

Warehousing and logistics: we supply all in-stock products (wear and spare parts) even outside normal business hours, e. g. by courier or collection. Our proximity to Düsseldorf Airport and motorway links enables us to ship parts at high speed.

Discover more

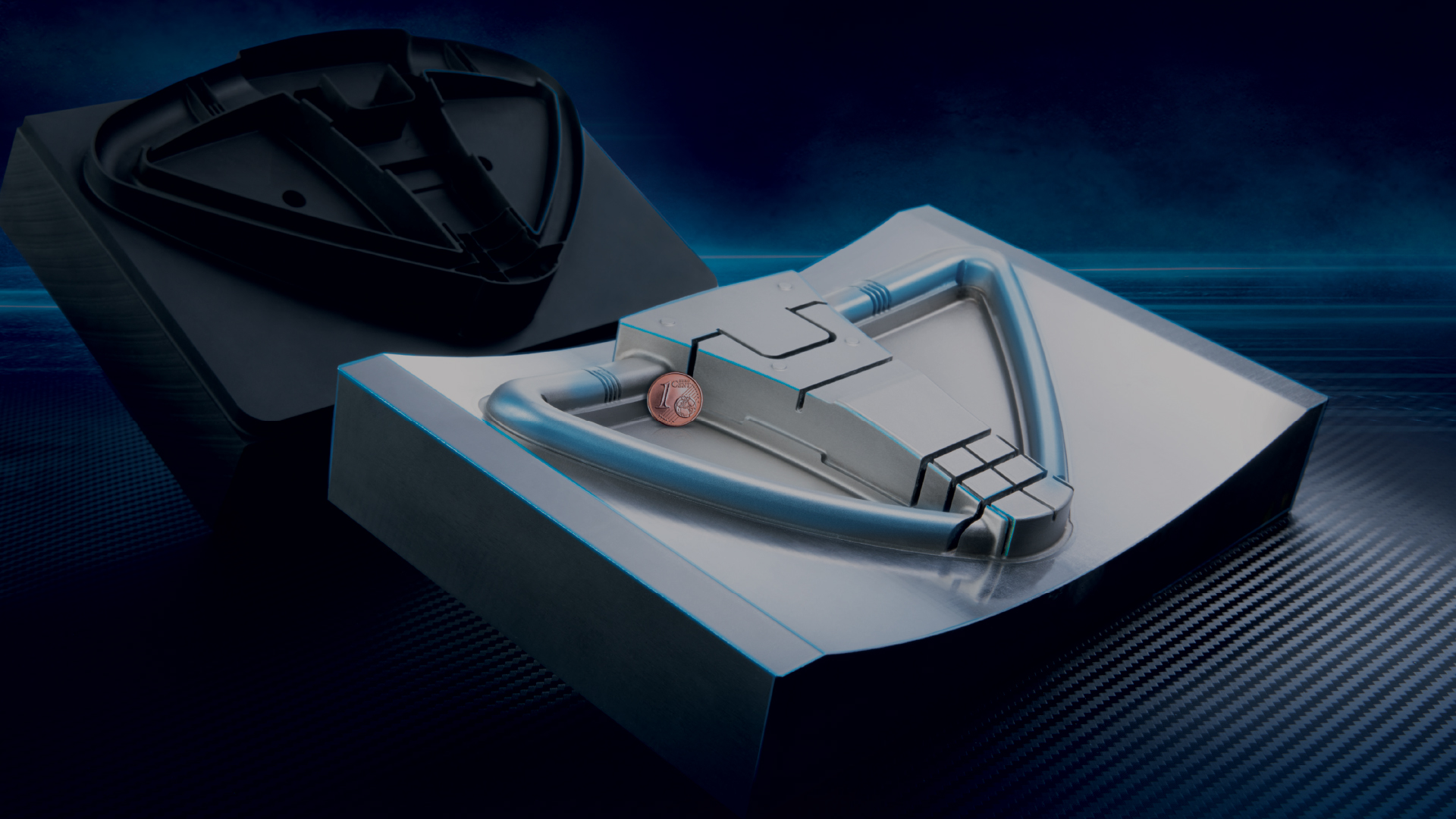

Die Sinking – Power for Precision

The rock-solid machine base of the SG series is your assurance of precision and durability. The choice of high-class components ensures the long-term reliability of the machine system.

The simplicity of the control and the programming itself – a hallmark of EDM machines by Mitsubishi Electric – allows the operator to focus on the essential, i. e. the proper planning of the various eroding tasks. And here, too, this is aided by the intelligent control strategy with integrated job planning and an efficient evaluation of a wide range of operating data, including actual job costing.

The full standard equipment of the SG-R completes the package. A fire extinguishing system, C axis with a zero-point clamping tool, external programming software – all this is part of the standard equipment. Additional useful features enable you to tailor the configuration to your individual requirements.

Discover the SG-R Series

Wire Erosion

The Power Master Control gives the most highest level of process stability – whatever the shape being cut. Stepped workpiece shapes, boreholes and other obstacles to a stable cutting process are identified as soon as they appear and the control adopts cutting and flushing parameters for a safe process and superlative accuracy.

On small inner and outer corners and complicated geometries, Corner Master 3 comes to your aid. You merely define your priorities, and optimisation is performed accordingly.

With precise control of the electrical discharge position, material is only removed where it needs to be. The patented functions of the Digital AE II improve rough and fine machining and fine finishing – in terms of both precision and machining time.

Discover our MV-R SeriesFields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com