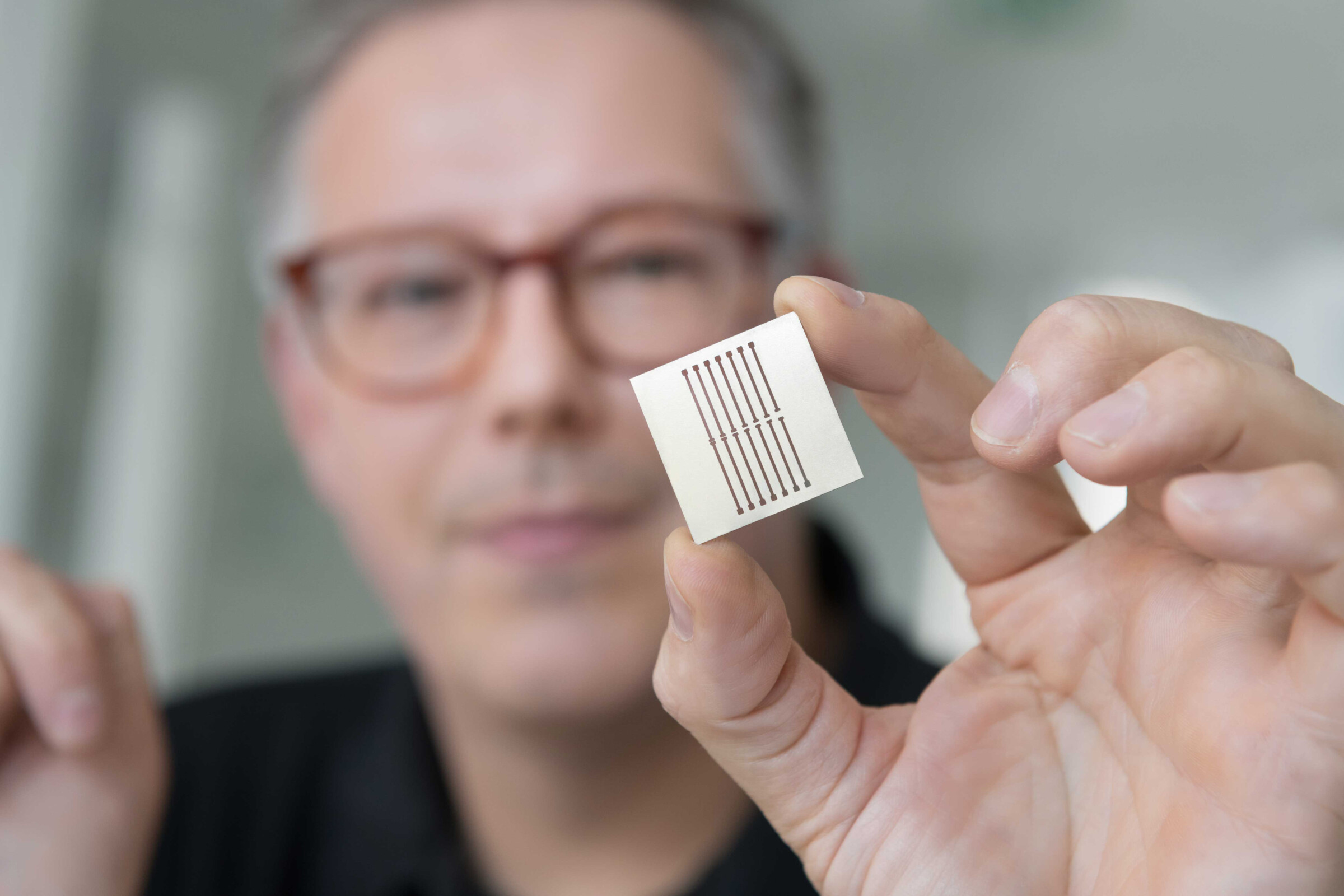

Combining precision and technical expertise with excellent service is the daily motivation of Peter Müller, Managing Partner of esm Erodier-Service-Müller GmbH. For him it is important to generate tangible added value for customers with his work. His machinery therefore always has to be regularly optimised in accordance with the customer’s wishes. The entrepreneur’s wish list recently included an EDM machine that also cuts over 300 millimetre high workpieces perfectly. esm found what it was looking for at Mitsubishi Electric. The Mitsubishi Electric MV2400RZ+ Connect has impressed them with its high quality, user-friendliness and a cutting height of 425 millimetres.

Funded by the Federal Ministry of Economic Affairs and Energy on the basis of a resolution of the German Bundestag

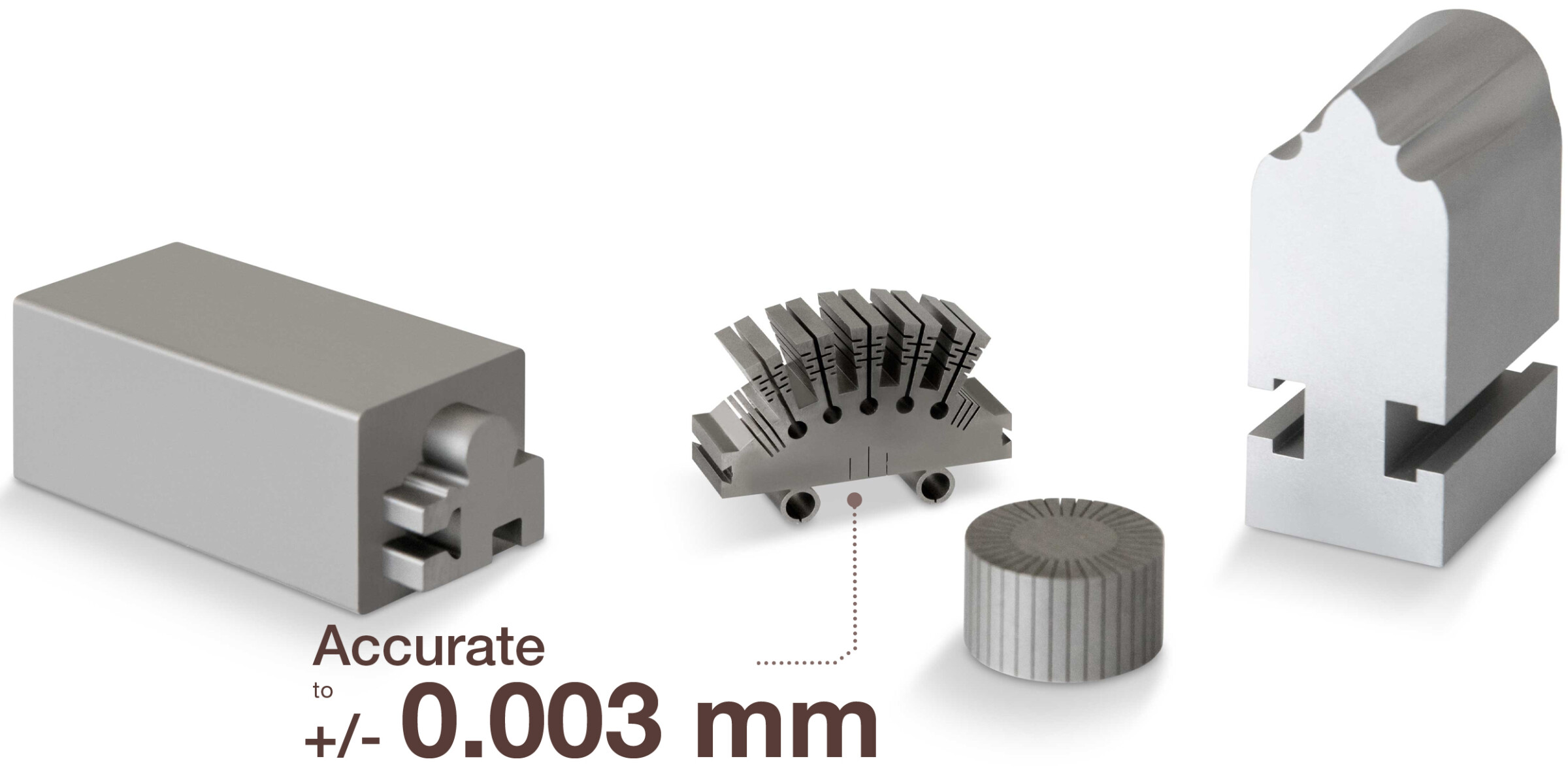

Cutting height evenup to 425 mm. Steel component with DIN 5480 toothing.

Wolfgang Müller founded the company in 1989. His many years of experience in the field of die-sinking and wire-cutting provided a solid basis for starting up the business and have also ensured the company’s success in the long term. Within a few years, the equipment at esm Erodier-Service-Müller GmbH grew from one to ten machines and the production area increased rapidly to 350 square metres.

With a constant stream of new customers and larger orders, esm reached its limits at the company base in Kronberg in 2015. There was not enough space for further growth with new staff and new machines. This also marked the moment when management of the company was handed over to the company founder’s son Peter.

“I gave taking over the company a lot of thought and looked very closely at how my father had successfully built up the company over 25 years,” Peter explains, “and then put service and customer care at the top of the agenda.” The customers are comprehensively advised from the very beginning and informed immediately when the job is finished. It is important to Peter that his customers are fully involved in service provision. “This also includes the fact that we always quote a price within 24 hours,” he says. Before getting started, esm lays down the processing steps together with the customer, so that the customer also has the opportunity to point out the special features of his workpieces. “We often receive parts that have already been extensively pre-machined,” Müller explains. “Then there are often many thousands of euros in the workpiece that the customer has already invested in machining. We are very focused on appreciating these machining efforts and handle the workpiece with the appropriate care.” For esm, an order does not end with delivery or invoicing. For Müller, a good after-sales service making sure the customer is happy is an integral part of every assignment.

3.20 mm-diameter micro gearwheel with 16 teeth, material brass (CuZn40Pb2)

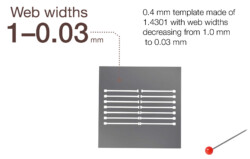

3.20 mm-diameter micro gearwheel with 16 teeth, material brass (CuZn40Pb2)Since its founding, esm has concentrated exclusively on erosion. Thanks largely to its decades of experience, the company’s services are much sought-after in the sector. As a subcontractor, esm offers the full range of machining options from wire cutting to die sinking, bore and micro-erosion. For example, the company produces fully hard-eroded items and precision mechanical components with high standards of precision for classic tool- and mouldmakers. Customers from the medical technology and metrology sectors appreciate the company’s comprehensive expertise in the erosive machining of such special materials as silicon carbide, tungsten carbide, titanium, tantalum and platinum iridium.

Component manufactured with 0.10 mm wire for high standard of surface quality, material 1.2379, hardened

Müller also attaches importance to working with research institutes, precision engineering and microtechnology companies as well as start-ups. “They are not usually among the high-turnover A-customers. But with their sometimes challenging orders and complex requirements, they enrich our knowledge and broaden our conceptual horizons,” says Müller. “What counts for us is the end product and the way to achieve the optimum result as cost-effectively as possible.”

Small parts are also eroded with precision on the large machine. Here an esm logo machined with 0.10 mm wire, character height 1.5 mm, material 1.4301.

“Sustainability is currently on everyone’s lips,” says a surprised Müller. “At esm we have been practising it for ten years with great success. This included switching at the time to a green electricity supplier – a pretty unusual step in the industry at the time.” The company has been proactive with this strategy and has spread the word in the marketplace. “Our customers’ response has been astonishingly encouraging. I had not expected so much positive feedback,” Müller says enthusiastically. The construction of the new company building offered Müller the chance to push ahead with his ideas on sustainability. The building is built energy-efficiently and equipped with highly advanced LED lighting. Both the heating and the air conditioning for production run very inexpensively and efficiently via several heat pumps. “We pay attention to the little things,” Müller reports. “Among other things, we have banned plastic packaging and bottles and give shipment packages a second life.”

Wire EDM Team Leader Rainer W. with a 350 mm long toothed component

In order to meet its high quality standards, esm regularly invests in its machinery. “In the last four years,” says Müller proudly, “we’ve purchased three new machines and thus upgraded a third of our equipment. We finance all our investments exclusively from our own funds. This is by no means commonplace nowadays and in the present market conditions, and it shows that we are building on a solid foundation.”The most recent purchase was a Mitsubishi Electric MV2400RZ+ Connect. For almost 30 years, the only wire-cut EDM systems in the esm shop were all from a different manufacturer. “We were basically satisfied with these machines,” says Müller, “but we were only able to cut workpieces up to 300 millimetres high.” So the company needed a machine for greater cutting heights. “We discussed the matter at great length with our staff and weighed up the pros and cons of changing the machine set-up,” says Müller. “In the end, we decided on the Mitsubishi MV2400RZ+ Connect.”

The MV2400RZ+ Connect also excels with delicate contours.

Decisive for Müller in switching to Mitsubishi Electric were the performance data with a cutting height of 425 millimetres and the quality of the machines. In addition, Müller insisted on working with a competent and efficient manufacturer that provides comprehensive and rapid after-sales service. esm has paid special attention to having a broad market presence. “We know that Mitsubishi has a lot of machines on the market, is vigorously developing its systems and is also investing in research,” Müller explains. The machine has been in operation in esm’s production shop since May 2022 and initial experience has been very positive. “We haven’t needed on-site service yet, but we have used the telephone service for queries,” Müller reports. “The hotline is quick and competent. So far we’ve been able to solve our problems within one to two hours of the call.”

Components made of steel, some machined with 0.1 mm wire and Aluminium component with complex 3D contour

Funded by the Federal Ministry of Economic Affairs and Energy on the basis of a resolution of the German Bundestag

“During the decision-making process, Michael Willwacher from Mitsubishi agent Willwacher pointed out the funding opportunities available from BAFA, the German Federal Office of Economics and Export Control,” Müller recalls. Initially sceptical, he decided to apply for funding after all. Together with his tax accountant and his wife, who also works for the company, he gathered all the data and filled out the detailed forms. Around two months after the application, the decision came. “BAFA financed 50 per cent of our investment in the new Mitsubishi MV2400RZ+ Connect,” says Peter Müller enthusiastically. “Brilliant! And a win-win for us and our customers!”

Name and place of company:

esm Erodier-Service-Müller GmbH

Germany

Founding year:

1989

Managing partner:

Peter Müller

Employees:

7

Skills and core competences:

Fully hard-eroding classical tool and mould components, precision mechanical components to high standards of precision, components for medical technology and metrology, high level of expertise in the erosive machining of such special materials as silicon carbide, tungsten carbide, titanium, tantalum and platinum iridium

All EDM methods: wire cutting (6 machines), die sinking (3 machines), hole drilling (2 machines), die-sinking of tungsten carbide

High level of expertise in cooperation with research institutes, universities and start-ups/prototype production

esm Erodier-Service-Müller GmbH

Karl-Hermann-Flach-Strasse 27

61440 Oberursel

Germany

Tel. +49 (0)6171 2877728

Fax: +49(0)6171 2877727

info@esm-mueller.de

www.esm-mueller.de

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com