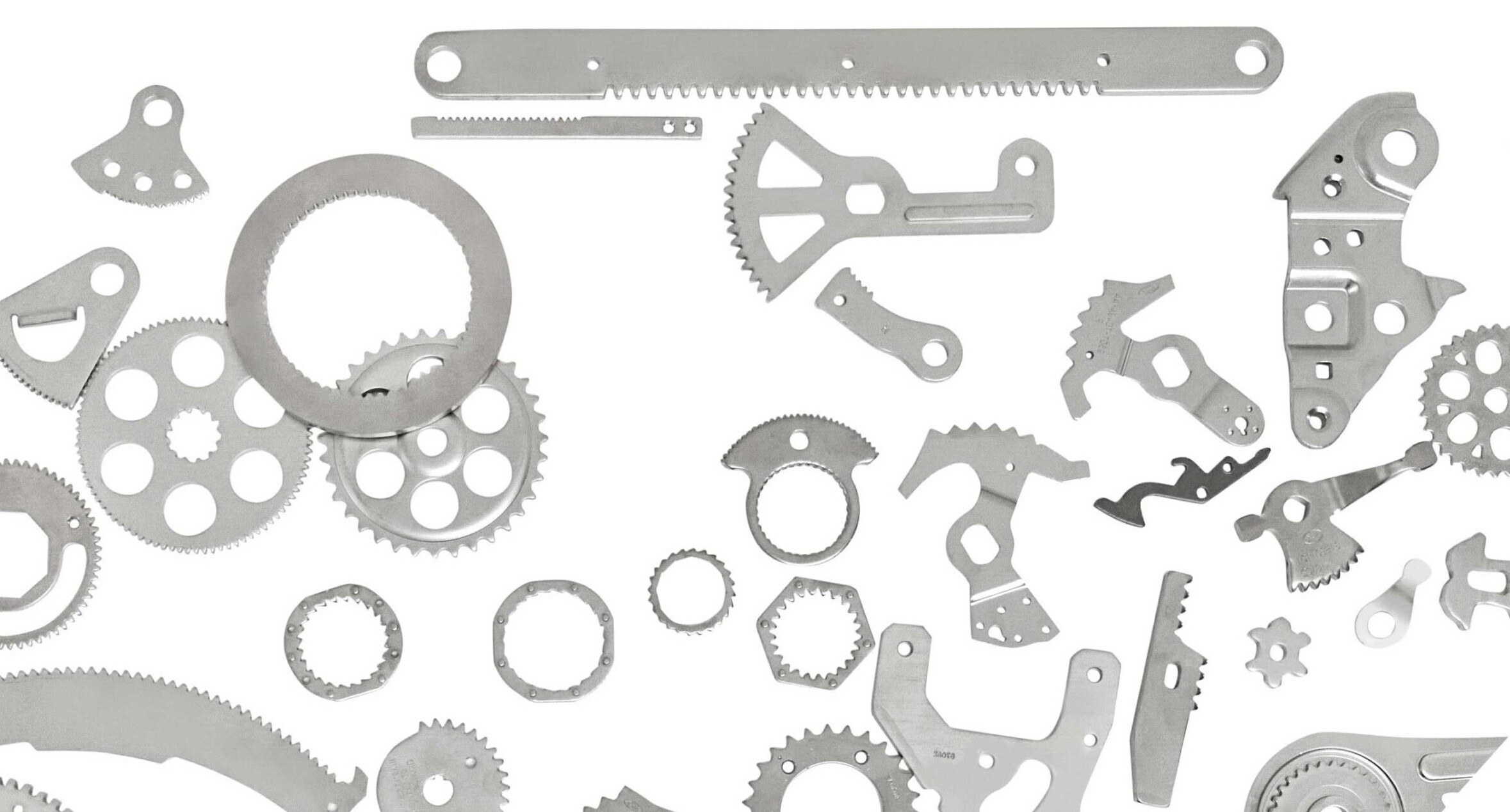

There is hardly an object in everyday life that does not contain sheet metal parts. Whether it’s a car, computer, music system or kitchen appliance, numerous sheet metal components can be found literally everywhere. Most of these are created by stamping, a powerful and cost-effective technique. For some applications, however, the quality of the parts produced with this method is not sufficient. This is where fine blanking comes into its own, a technology similar to stamping but which delivers much better precision in terms of both contours and cut edges.

Tool assembly calls for the utmost care. Only in the hands of genuine experts do the best production tools become a true factor for success.

Reto Bamert, head of Sales/Marketing at Feinstanz AG

“We are manufacturers of high-precision components, many of which are ready for assembly almost straight from the tool,” explains Reto Bamert, Head of Sales/Marketing at Feinstanz AG in Rapperswil-Jona, Switzerland. Its main customers are the automotive industry, kitchen and furniture makers, machine manufacturers and makers of equipment for building services and ventilation.

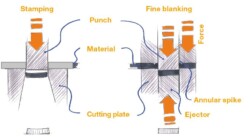

Production in the company revolves around stamping and similar processes, but the fine blanking technology used is considerably more complex and delivers much more precise components than classical sheet metal stamping. The difference lies primarily in the tools. In conventional stamping, the gap between the punch acting from above and the die positioned beneath it is comparatively large. This means that the sheet is only cut smoothly at the beginning of the stamping process. The remaining removal of material, on the other hand, is not done by cutting, but more or less by tearing. This part of the cut edge is then not only significantly coarser, but is also no longer perpendicular to the sheet surface.

In fine blanking in particular, the earlier in the development phase we can work together with the customer, the more they usually benefit.

Reto Bamert, head of Sales/Marketing at Feinstanz AG

In fine blanking, the width of the gap between punch and die is only about one tenth of what is usual in stamping. The sheet metal is also pressed down around the kerf with an annular spike so that the material cannot flow away. The result is a right-angled cut with an absolutely smooth edge. Depending on the sheet thickness, the parts achieve dimensional accuracies of less than 5 µm in some cases.

“For fine blanking, progressive dies are often used that can carry out various forming processes such as notching, embossing, piercing and even impact extrusion in timed steps in addition to fine blanking,” Bamert adds. The result is high-quality, in some cases highly complex, structured components with three-dimensionally variable geometries.

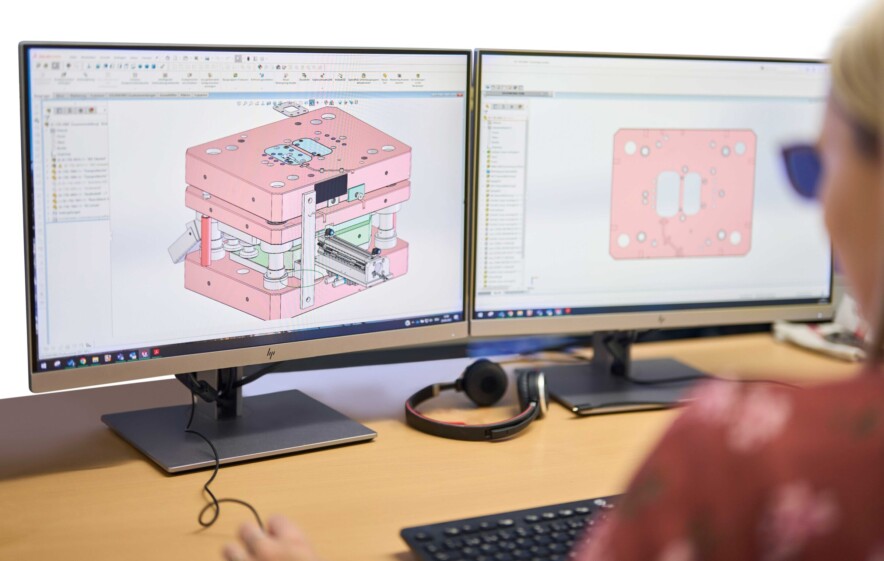

Customer advisors have the latest programs for design and simulation at their disposal.

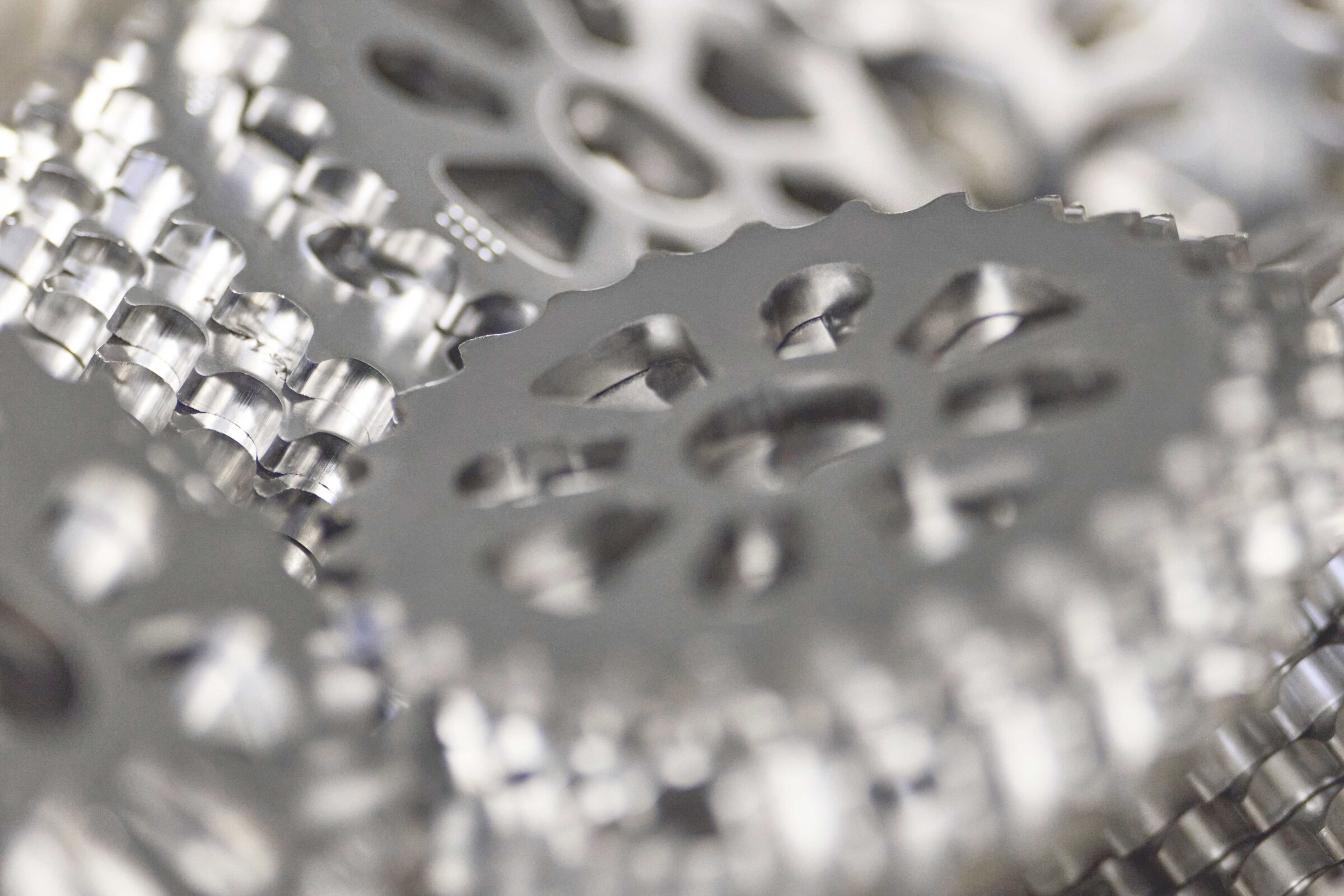

The dimensional tolerances and surface qualities are often the same as those of milled or turned parts. Examples include sprockets with intricate gearing, control cams on furniture fittings that no longer need reworking, and a component for the automotive industry that was originally designed as a milled part with complex 3D geometry that comes out of the tool completely ready for installation. The technology is efficient because numerous individual steps are combined in succession in the progressive die and no further mechanical working is usually required on the part afterwards.

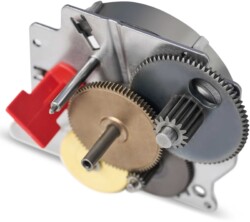

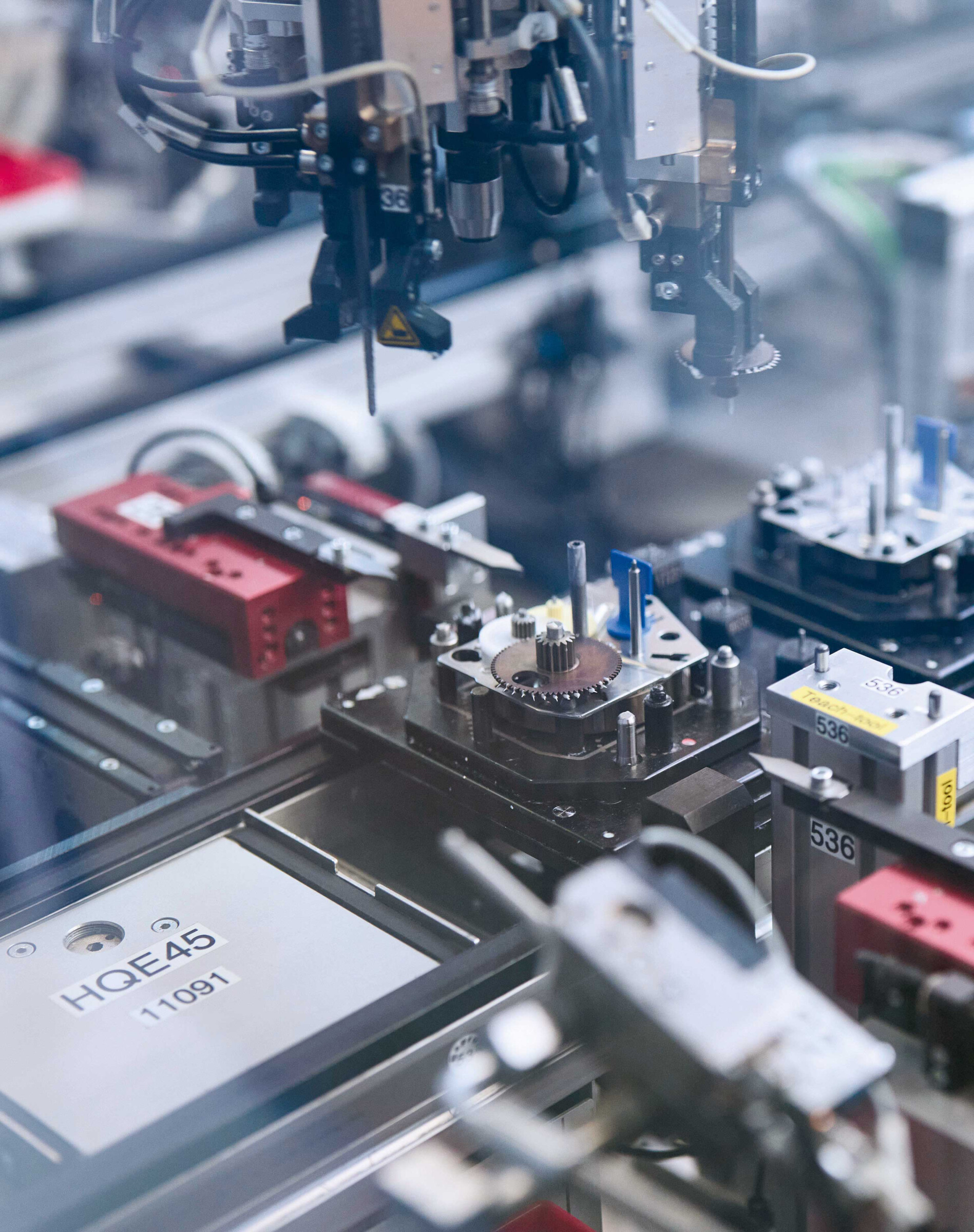

Composite part supplemented with bought-in parts and assembled ready for installation: actuator for ventilation flaps

For example, with the aid of piercing it is possible to produce the axes of a planet carrier with a basic ISO tolerance of IT 8. Due to the combination of numerous operations in a single pass, so many additional operations can often be saved that the process proves on balance to be the most cost-effective option.

“In fine blanking in particular, the earlier in the development phase we can work together with the customer, the more they usually benefit,” says Bamert. An important consideration here is the possibility of integrating additional functions in the same part thanks to the numerous possible tweaks on its passage through a progressive die.

This can save the production and attachment of additional parts and/or further machining processes. The advantages when considering the process chain as a whole are often substantial. However, this requires the customer’s developers to discuss their ideas with the design engineers at Feinstanz as early as possible at the design stage. The latter can then contribute their knowledge of the fine blanking process to the discussion so that the parts are designed from the outset to maximise the benefits possible in the process.

This can save the production and attachment of additional parts and/or further machining processes. The advantages when considering the process chain as a whole are often substantial. However, this requires the customer’s developers to discuss their ideas with the design engineers at Feinstanz as early as possible at the design stage. The latter can then contribute their knowledge of the fine blanking process to the discussion so that the parts are designed from the outset to maximise the benefits possible in the process.

An example of this is the swash plate of an axial piston pump, which only needs flat grinding on both sides after fine blanking. For such collaboration, the long-standing fine blanking employees in the design office have the latest design and simulation software at their disposal, as well as the option of producing prototypes for trials.

“Another key service we can offer our customers is an extension of our own value chain tailored precisely to their needs,” Bamert reveals. In principle, this includes everything required to deliver a product or an entire assembly to the customer in exactly the condition they need for immediate use in production.

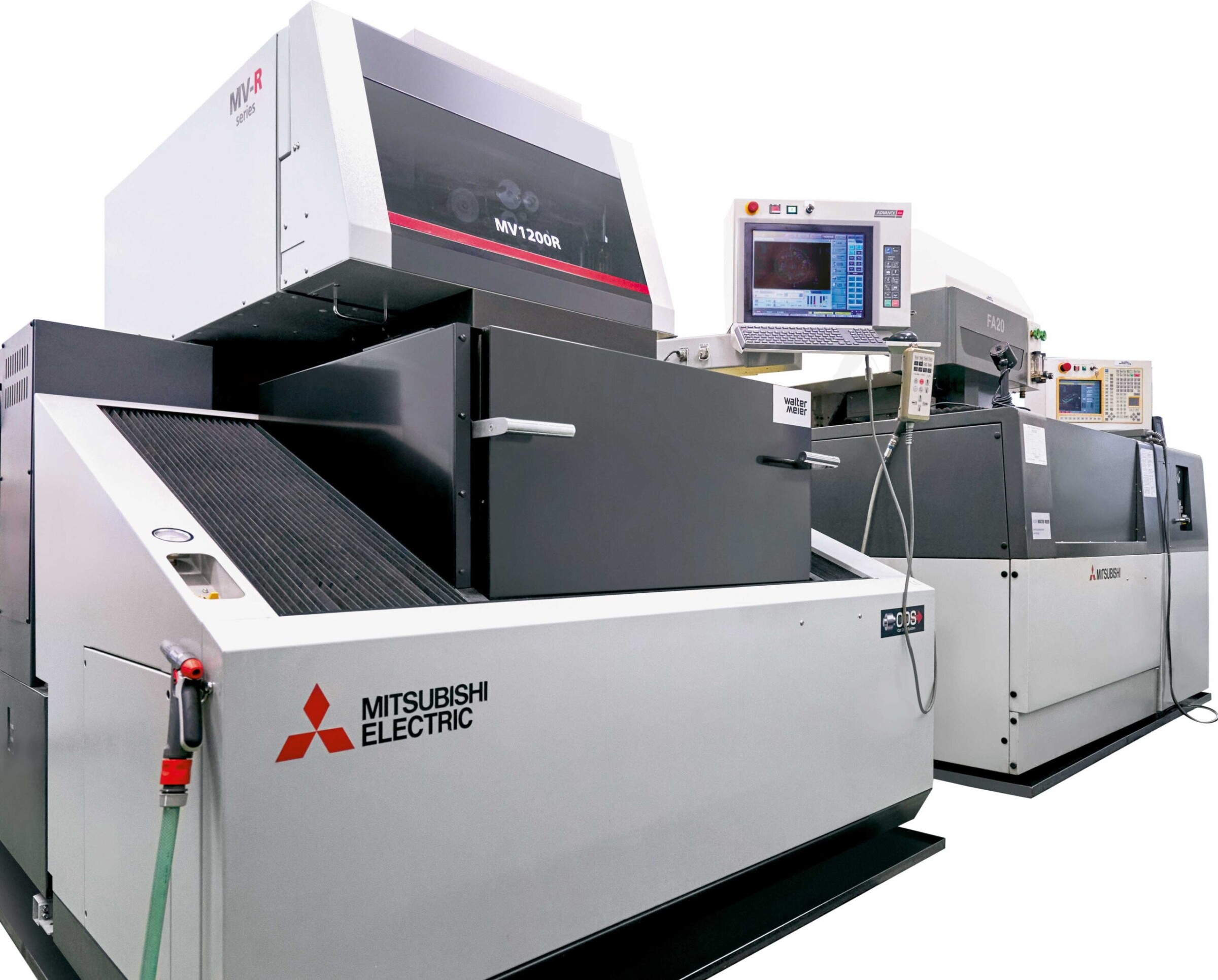

The punch and die for a sheet metal part are cut by wire erosion from hardened tool steel several centimetres thick.

This comprises all conceivable additional machining such as surface grinding, turning, cylindrical grinding and laser marking, and also, for example, the silver-plating of aluminium bus bars. Further steps included the addition of bought-in parts such as threaded bolts, springs or gear wheels and assembly, quality control and blister packaging. The customer thus receives fully functional assemblies such as actuators for ventilation flaps for building air conditioning. Such work is carried out manually or with partial or full automation in robotic production cells, depending on the requirements. Bought-in parts and services such as silver-plating are procured externally from a network of proven providers. Feinstanz assumes sole responsibility for the overall service delivered to the customer.

Marco Rauchenstein at the control of “his” MV1200R

“While we source our machines and peripheral components for our tools externally, we always make the crucial tool components such as punches and dies ourselves,” Bamert discloses. This is the company’s decisive expertise, and it is not only the design engineers’ skills that count, but also the workshop employees’ experience and attention to detail.

After all, the tools in production have to run in some cases at high stroke rates despite large sheet thicknesses of up to 14 mm. In view of the enormous loads they have to withstand, wear is inevitable, and this can also affect the quality of the cut edges of the parts. The greater the care in making and maintaining the tool, the longer it can produce flawless parts.

The two Mitsubishi Electric systems prove to be reliable and patient workhorses in daily use that can always be relied on.

Marco Rauchenstein, skilled mechanic at Feinstanz AG

Fine-blanked parts are produced in an almost countless diversity of shapes for a huge variety of uses.

The combination of fine blanking and forming offers Feinstanz’s customers a wide range of design options for complex and precise multifunctional parts.

“We create the contours of the punches and dies for our tools by wire erosion on two Mitsubishi Electric machines,” says Marco Rauchenstein. The skilled mechanic has been responsible for this department and thus for the quality of the fine blanking tools in the company since 2014. The latter is to be taken literally, because the tool contours decisive for the accuracy of the fine-blanked parts are made from plates of hardened tool steel several centimetres thick. After wire cutting, their contours do not undergo any further machining. A 20-year-old FA20 wire EDM and an MV1200R commissioned in 2015 are used. Both machines operate with deionised water.

A particularly high degree of rationalisation is achieved in the fine blanking of gearing. Feinstanz AG’s expertise permits the fine blanking of high sheet thicknesses with small tooth modules.

The path data supplied by the design department in DXF format are supplemented with material parameters and then converted into specific machining programs via CAD/CAM. Both machines – including the “veteran” FA20 – achieve the required accuracy without any problems, but the newer MV1200R is about 30% faster. He services the systems himself once a month and they have been running without any major malfunctions over the many years. Should any issues arise, these are quickly and competently resolved by Binkert, Mitsubishi Electric’s Swiss agent.

The seven-year-old MV1200R (front) and the 20-year-old FA20 in the wire EDM department.

“The two Mitsubishi Electric systems prove to be reliable and patient workhorses in daily use that can always be relied on,” says Rauchenstein summing up his experience.

View inside a fully automated, robotic production cell for subassemblies

Name and place of company:

Feinstanz AG

A member of the Federtechnik Group

Switzerland

Founding year:

1958

Managing Director:

Florian Thoma

Employees:

Roughly 70

Core business:

Precision components in the fields

of fine blanking and component

assembly for the automotive industry,

kitchen and furniture making,

machine manufacture, and building

services and ventilation

Feinstanz AG

A member of the Federtechnik Group

Grünfeldstrasse 25

CH-8645 Rapperswil-Jona

Switzerland

Tel. +41 55 535 9900

fs@feinstanz.ch

www.feinstanz.ch

Mitsubishi Electric agent in Switzerland

Josef Binkert AG

Grabenstrasse 1

CH-8304 Wallisellen

Tel.: +41 44 832 55 55

Fax: +41 44 832 55 66

info@binkertag.ch

www.binkertag.ch

Fields marked with a * are mandatory.

Mitsubishi Electric Europe B.V.

German Branch

Mitsubishi-Electric-Platz 1

D - 40882 Ratingen

Sales

Tel.: +49 (0)2102 / 486 - 6120

edm.sales@meg.mee.com

Service

Tel.: +49 (0)2102 / 486 - 7600

edm.hotline@meg.mee.com

Applications

Tel.: +49 (0)2102 / 486 - 7700

edm.applikation@meg.mee.com

Spareparts

Tel.: +49 (0)2102 / 486 - 7500

edm.parts@meg.mee.com